MACHINE MONITORING

JITbase Machine Monitoring software automatically and accurately tracks production KPI, without human input.

Supervisors and operators can react faster on the shopfloor thanks to real-time information.

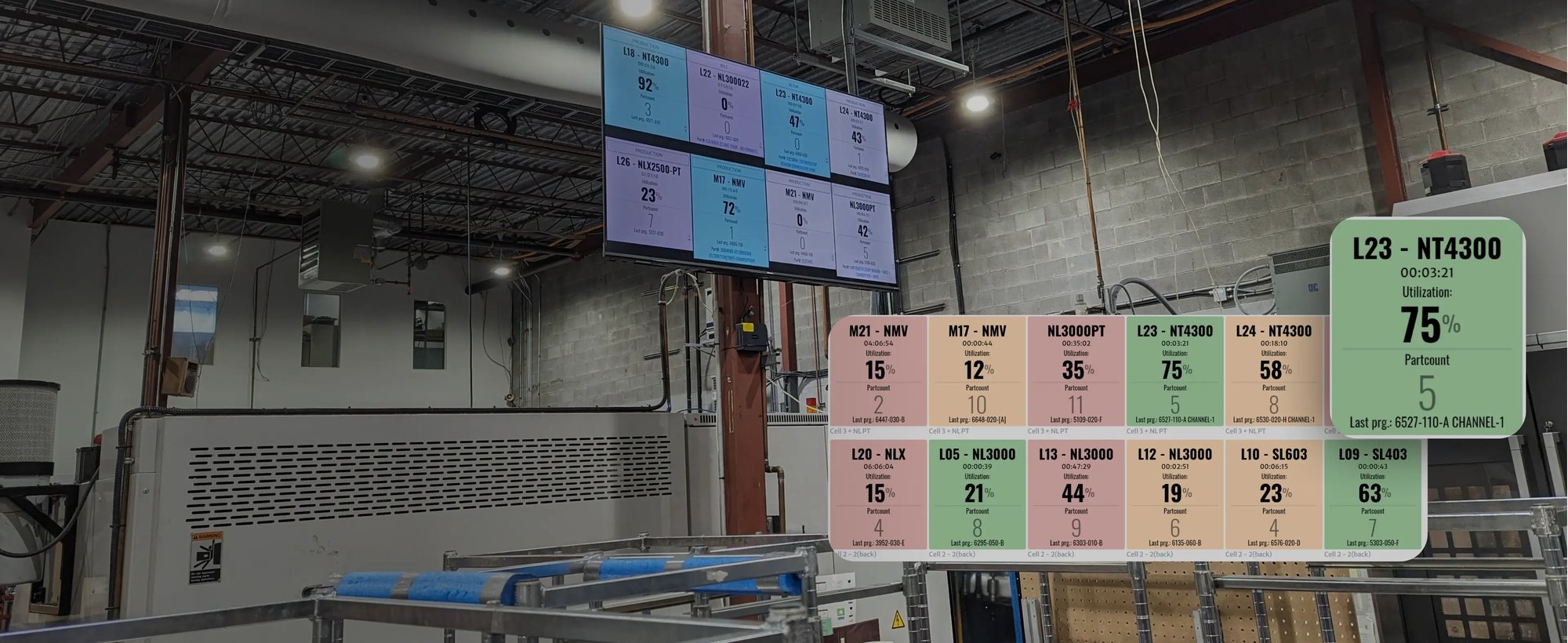

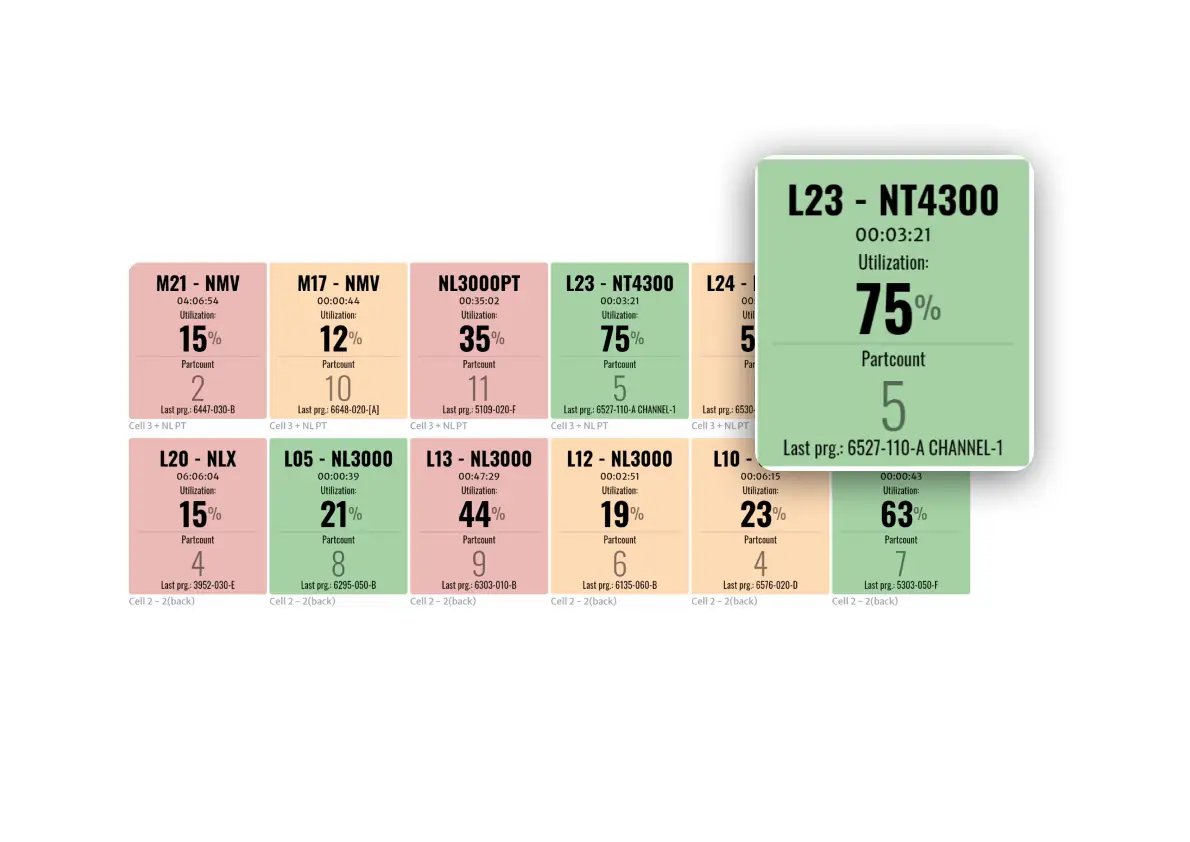

Live Production Dashboard with OEE

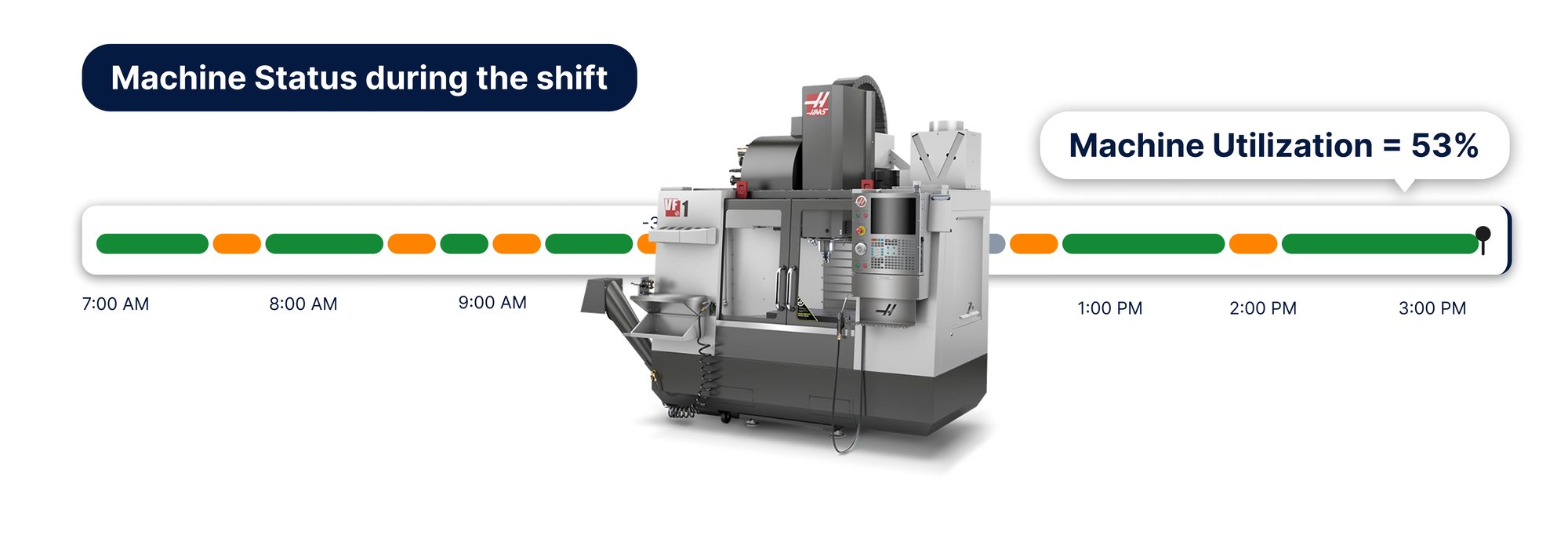

The machine monitoring dashboard displays machine status using real-time monitoring. Supervisors react faster to problems, resulting in less machine downtime.

Everyone on the shop floor understands the machine utilization, running programs and quantities produced by program, making the workforce accountable and eager to reach their objectives.

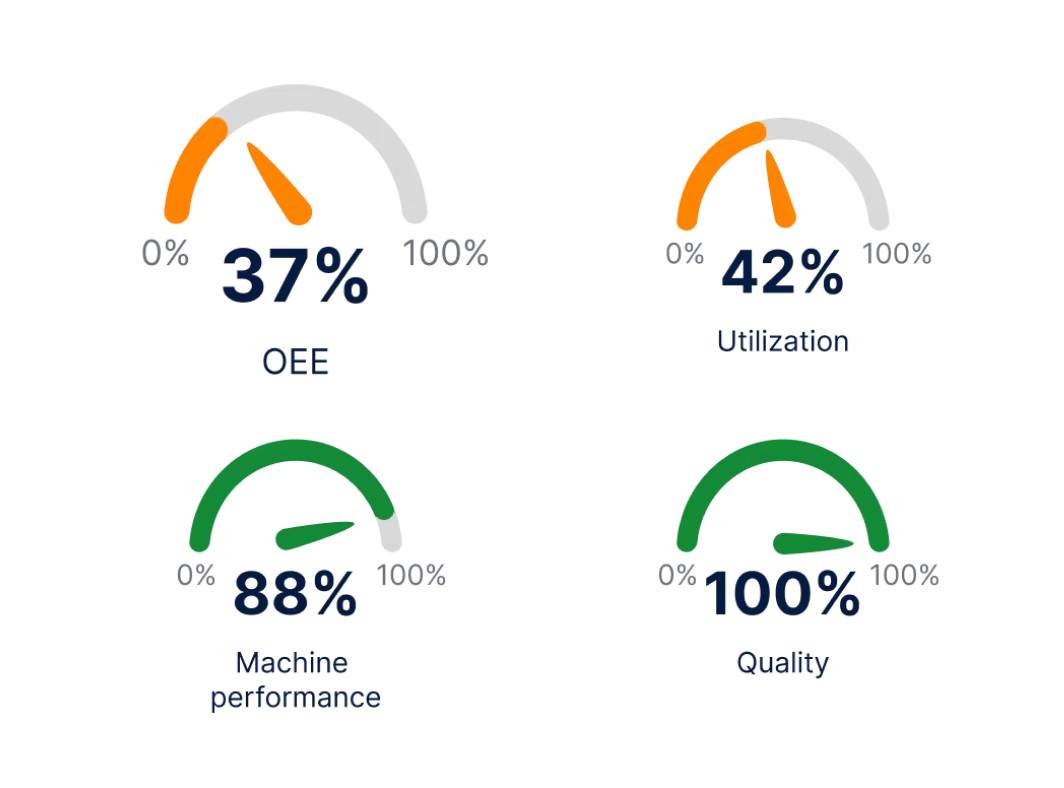

Overall Equipment Effectiveness (OEE) Machine Monitoring

JITbase is a real-time OEE monitoring system which allows you to automatically calculate and track OEE accurately thanks to live machine data.

Unlike traditional Machine Monitoring Systems that only track Machine Utilization (Uptime vs. Downtime), JITbase provides the Performance rate by automatically learning from your CNC programs to get standard times and compare them to actual production time.

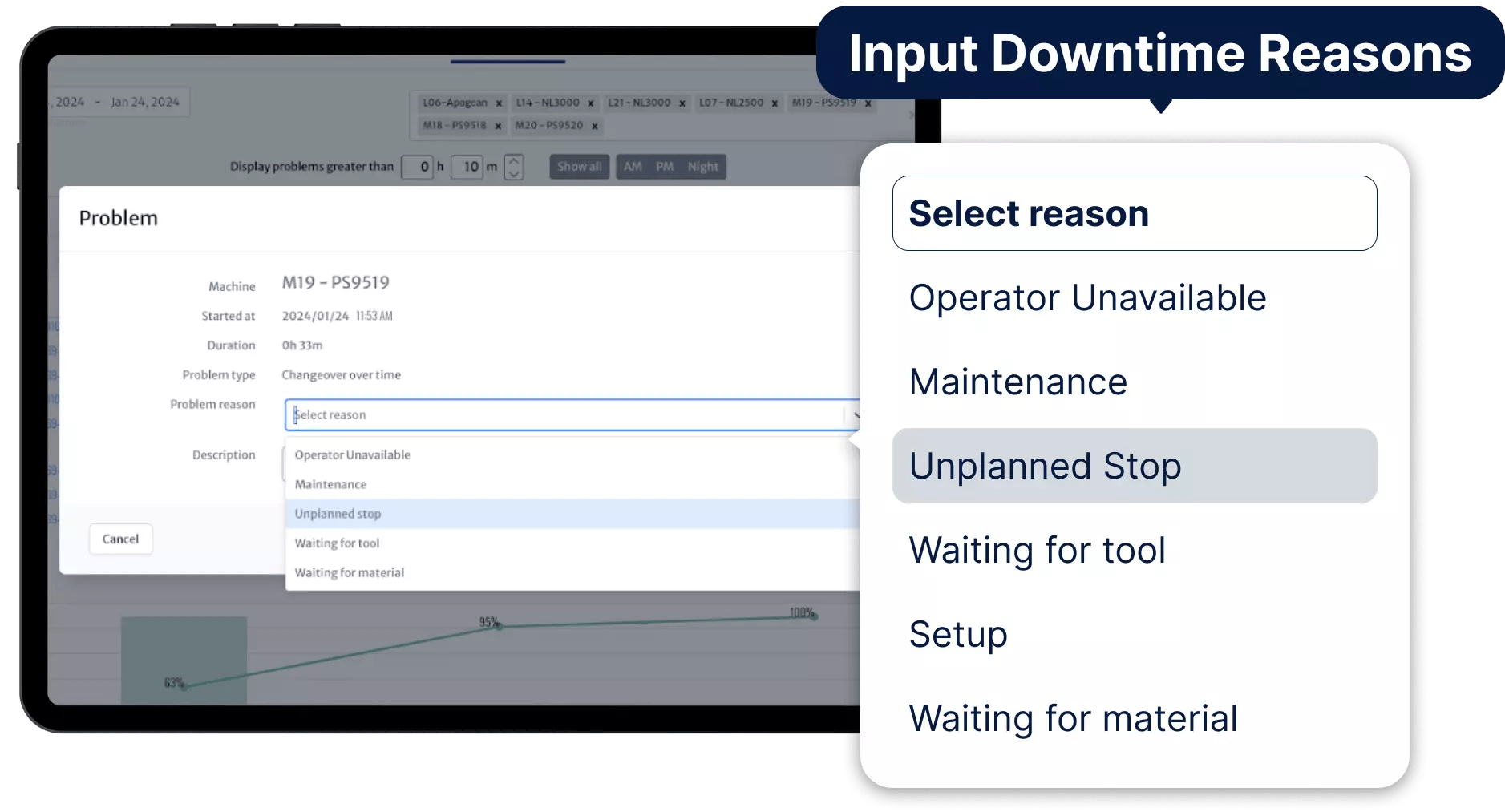

Machine Downtime Monitoring

JITbase is a complete machine monitoring software which helps you understand why your machines are inactive by letting operators input a downtime reason when a machine is stopped for too long. The output is a Pareto chart for you to address the most problematic reasons.

However, it is more effective to track Overtime Reasons. Learn more about Overtime Reasons here.

Production KPI Reporting

Track production KPIs such as OEE (Overall Equipment Effectiveness), machine utilization, performance rate & partcounts thanks to machine data monitoring

Managers monitor trends and make continuous improvements to increase production capacity. JITbase machine monitoring software automatically captures data from CNC controllers and helps to make data-driven decisions.

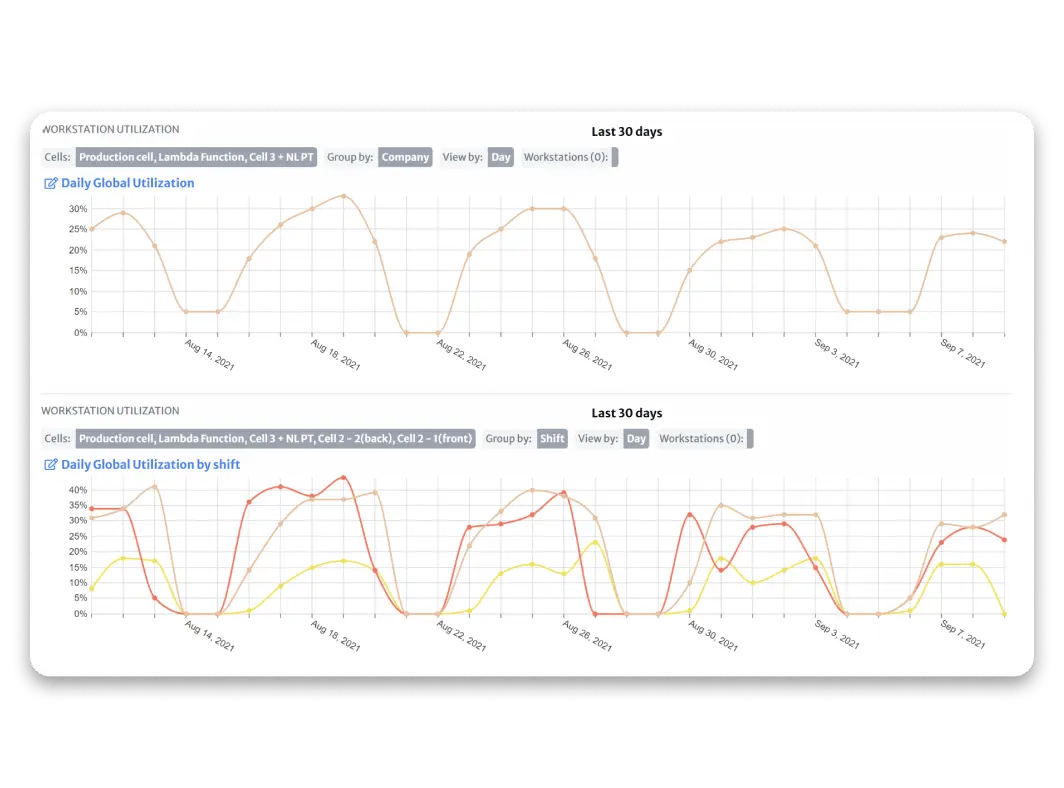

Analyze tendencies

Use data visualizations to view availability trends by week, month or year to gain insight into your productivity, and spot opportunities for improvement.

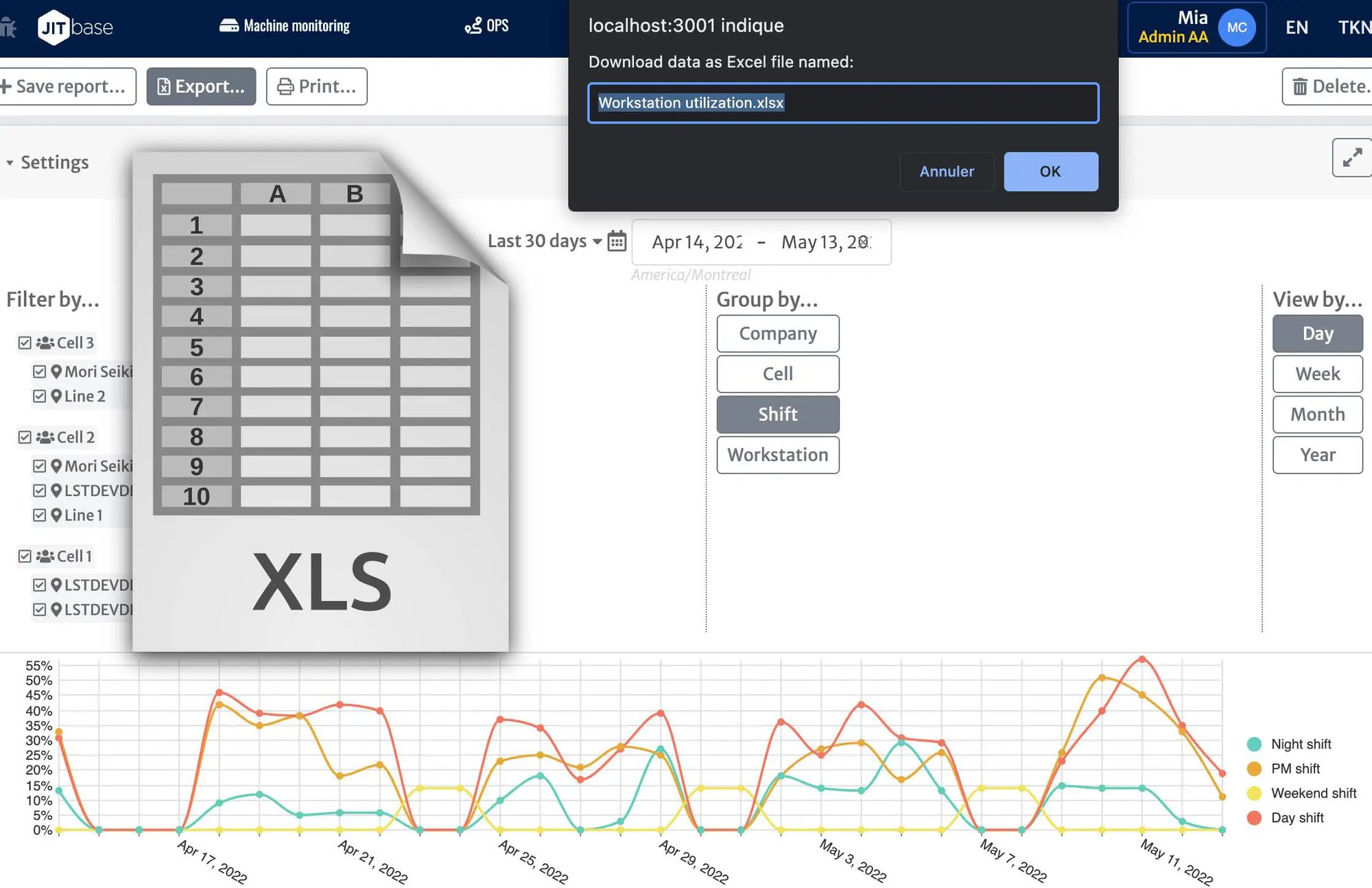

Data Export

Your data belongs to you. The JITbase web application enables you to export CNC machine monitoring data as an Excel spreadsheet so you can analyze the data however you want.

You can also automate the process using our API and create your own machine status dashboard or machine downtime dashboard.

CNC Machine Monitoring Systems provide limited or no payback

This is why JITbase was created. Looking at our competitors led us to the conclusion that existing CNC Machine Monitoring Systems provide machine uptime monitoring and metrics on your production, but do not help you improve it.

JITbase’s machine utilization software empowers manufacturers to maximize productivity by tracking CNC performance in real-time, allowing for data-driven scheduling and minimized idle time on the shop floor.

Learn more about how our CNC machine monitoring solution, powered by machine data, can truly drive up your productivity:

Get accurate standard times by CNC program

Get accurate standard times by CNC program

- Better costing in ERP system

- Better planning in ERP system

- Improve CNC programs by tracking performance

Simulate and track operator workload

Simulate and track operator workload

- Better daily allocation of operators to machines

- Find what combinations of programs/jobs a single operator can run

Provide live guidance to operators and supervisors

Provide live guidance to operators and supervisors

- Operators can manage more machines

- Supervisors track live progress and performance to adapt and respond more quickly

Ready to connect your machines?

Our Machine Monitoring System is free for up to 5 machines!

Sign up now and connect your first machine in no time through

our self-serve interface.

We provide a step-by-step guide and it can take less than 30 minutes.