Edge Platform

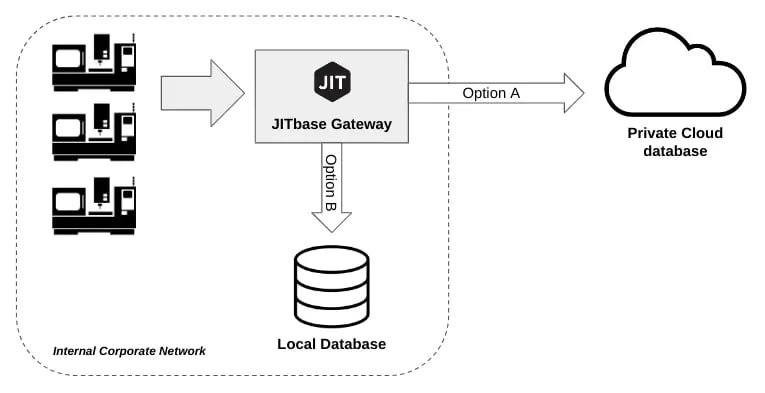

Use JITbase Gateway to manage the data flow from your machines to your own database. Manage & control your internal infrastructure and develop your own BI applications

Step 1

Install JITbase

Gateway in about 30

minutes

Installed on your machine network, the gateway will access any machine connected to the network. The goal of the gateway is to access raw machine data and to send it into a database.

Step 2

Add machines

Add machines by adding their IP address and port into the Edge Platform. We offer drivers for standard protocols such as MTConnect, Fanuc FOCAS or OPC-UA. Legacy machines can be connected by using an I/O box that converts electrical signals into MTConnect.

Step 3

Direct to your own Database

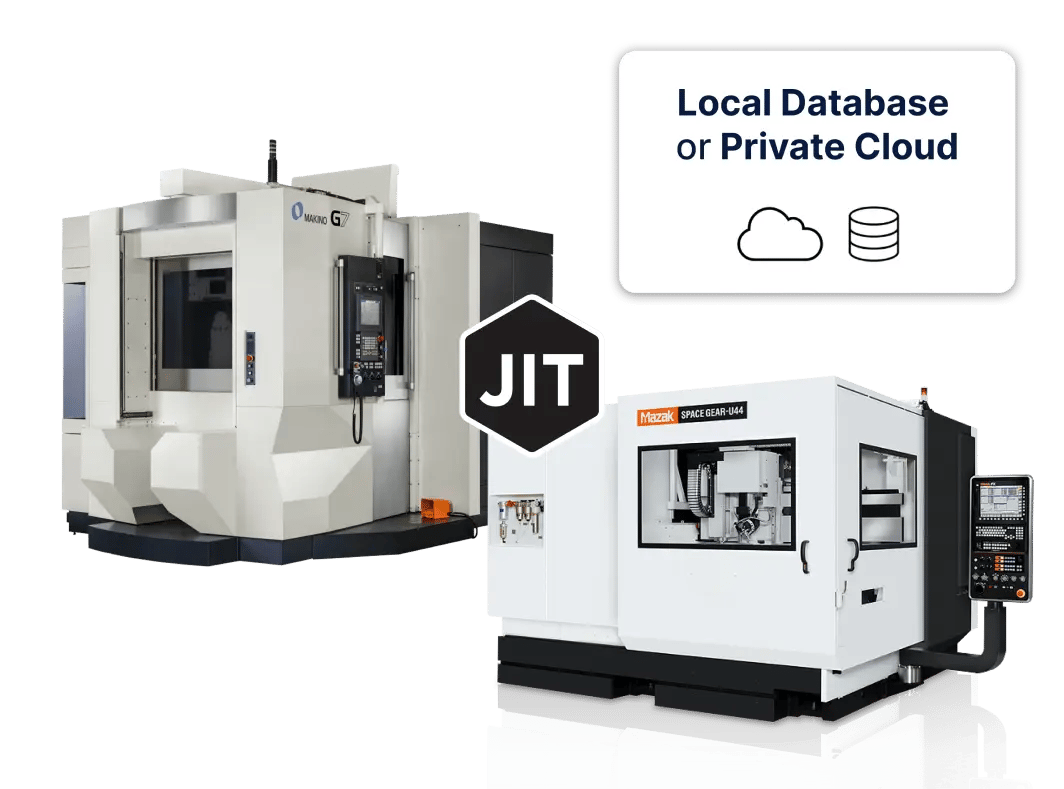

JITbase gateway is agnostic and can send raw data to a local database or a private cloud database. JITbase can also compile metrics such as the machine utilization, so that you have access right away to the relevant information without having to code anything.

Drivers for standard protocols

JITbase has proprietary drivers to communicate with any CNC machine with standard communication protocols, such as MTConnect, OPC-UA or Fanuc FOCAS. These protocols are used by most machine-makers. This include machines like Mazak, Okuma, DMG Mori, Matsuura, as well as machines using Fanuc, Mitsubishi or Siemens controllers.

Go to Machines we connect to find out how to connect your machines.

Integrations

The strength of Industry 4.0 is the interconnection of systems. JITbase provides an API to send data to or to receive data from your existing systems.

ERP / MES

- Send machine data to ERP or MES

- Automate job completion

- Automate inventory

- Automate setup or production clock-in and clock-out

- and much more...

Planning or APS

- Send jobs to plan to JITbase for daily scheduling

- Use JITbase to send real-time operation progress and/or completion to APS to reschedule optimal planning

BI

Send machine data to Power BI (or other BI tools) to build and visualize:

- Custom dashboards

- Custom reports

JITbase collects data on the workforce that no other solution on the market can provide. Benefit from this data by integrating JITbase into your current software infrastructure.

Download our Integration case study to better understand how JITbase and conventional Machine Monitoring Systems can be interconnected in the full manufacturing technology stack.