From ERP planning to real, algorithmic scheduling.

JITbase calculates the optimal production plan — based on your real constraints: machines, operators, shifts, routing, deadlines, and live WIP.

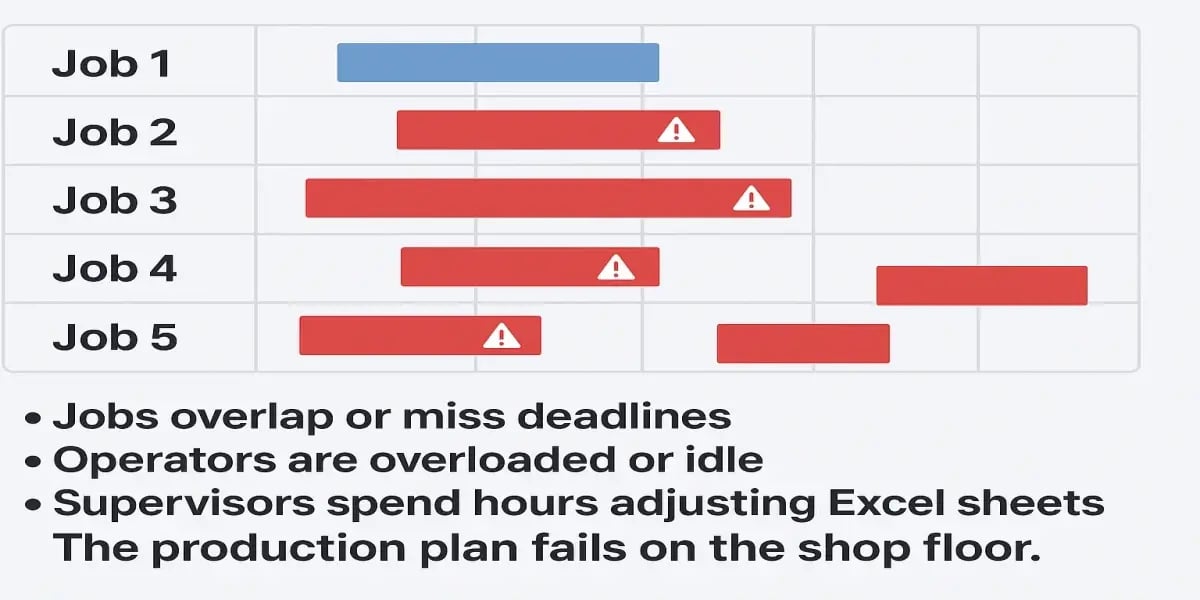

Infinite-capacity planning doesn’t exist in real life.

Most ERP systems assume every job can be planned regardless of who’s available, which machine is busy, or when the shift ends.

The result?

-

Jobs overlap or miss deadlines.

-

Operators are overloaded or idle.

-

Supervisors spend hours adjusting Excel sheets to fix the plan manually.

The plan looks perfect on paper… but fails on the shop floor.

Plan with real constraints not assumptions.

JITbase uses scheduling algorithms to build the optimal plan that respects every real constraint in your factory:

-

Work orders, operations, and routing

-

Machine and tool availability

-

Operator skills and shifts

-

Production priorities and deadlines

-

Live WIP and job progress

The system recalculates automatically every time something changes — so your plan is always feasible and up to date.

Real-time scheduling, recalculated automatically.

Unlike ERP “infinite capacity” planning, JITbase performs finite-capacity scheduling.

It instantly simulates all possible combinations of machines and operators to find the best sequence of jobs.

Every plan is based on:

- Real-time machine states

- Shift openings and operator availability

- Job routing and deadlines.

The result: a plan that’s achievable — not theoretical.

From reactive to proactive planning.

- Reduce scheduling time by 90%

- Eliminate daily Excel adjustments

- Improve on-time delivery rate

- Balance workloads across machines and operators

- Get a live, achievable plan — every minute of the day

Finally, a plan that matches what happens on the shop floor.

“With JITbase, we stopped fighting Excel every morning.

The system now gives us a feasible plan that adjusts automatically to real conditions.

Our planners can finally focus on improvement, not firefighting.”

— Daniel, Production Manager in a precision machine shop

See your real plan calculated by JITbase.

We can import your current plan (from Excel or ERP) and show you, in less than an hour, how JITbase recalculates it using your real constraints: machines, people, and shifts.