Overcoming Labor Shortage: Know Your Operators' Workload

Book a call with us

Understanding operator workload

In today's manufacturing landscape, the cry of labor shortage is a common refrain. Companies across the globe struggle to find skilled workers to operate machinery and maintain production lines. However, before we delve deeper into the issue of labor shortage, it's essential to address a critical question: Do you truly understand the workload of your current operators?

The major challenge in predicting operator workload is knowing the estimated durations of each task, which is generally not accessible. Indeed, in standard production software, such as ERP, MES, MRP or APS, only the adjustment time and the total production cycle are recorded.

Data Collection and Analysis

In lean manufacturing practices, times can be timed manually in order to understand the standard time for each operation. Generalized at the factory level, this practice represents a Herculean task, realistically difficult if not impossible to implement and above all to maintain.

- Setup Times

- Changeover Times

- Planned Stops (M00)

- Inspection Times

As JITbase collects this data we build up a repository of information which can then be used to predict upcoming tasks for the operators and predict their workload for a shift.

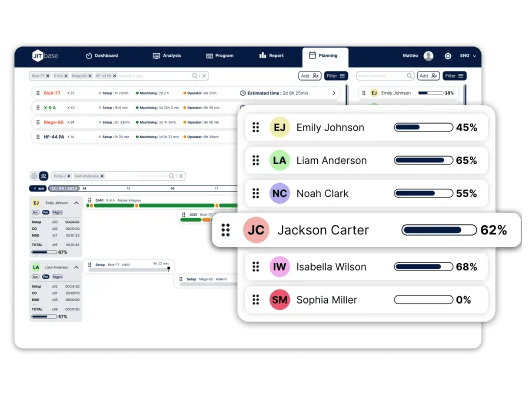

Smart and dynamic Operator Allocation

The reality of planning is rarely the reality of production. It is therefore essential to be able to adjust the production plan, almost in real time, depending on production hazards and emergencies that arise during the day.

Connected to the machines, the JITbase workforce planning and management tool updates in real time, based on actual production progress. It is therefore possible to readjust the assignment of operators throughout the shift, to maintain the highest possible level of productivity.

Supervisors who are generally in charge of daily planning and resource allocation on machines can now couple their expertise and experience with factual data that can guide them on essential decisions with a strong impact on the overall productivity of the plant.

We maximize machinists’ production efficiency

JITbase is the first system to use machine data in order to improve workforce efficiency.

Want to know more?