From an approximate OEE to a complete, standardized OEE

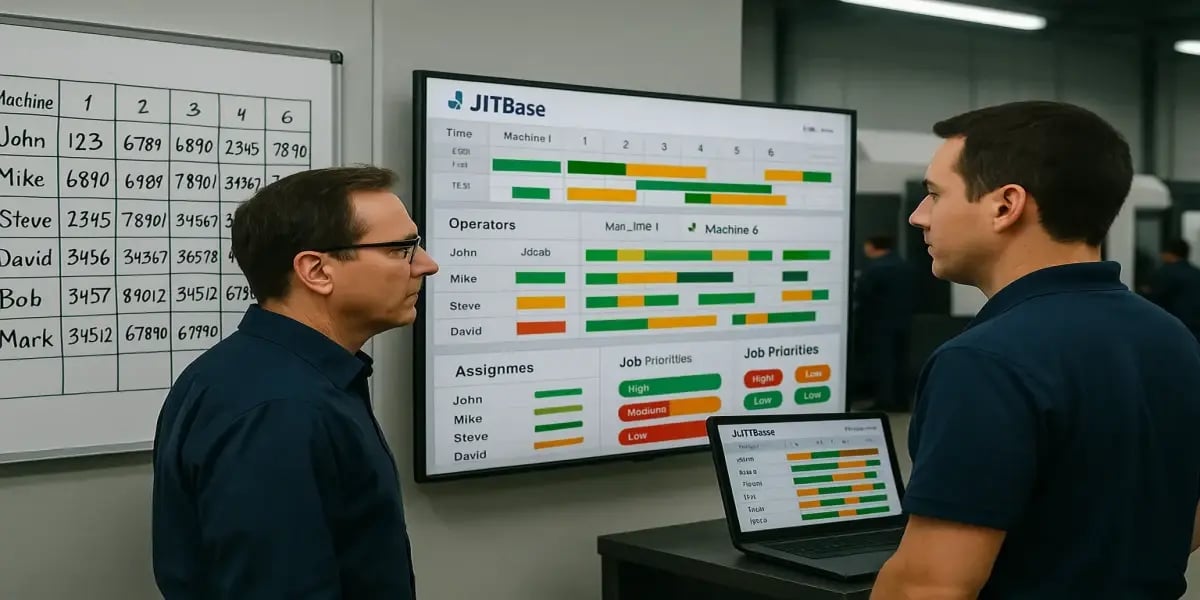

JITbase automatically calculates your performance indicators in compliance with the NF E 60-182 standard including OEE, OOE, and TEEP — using real-time machine and operator data, for reliable, actionable performance tracking across your shop floor.

OEE is often miscalculated

In most factories, OEE is calculated in the ERP or in Excel,

using incomplete or manual data:

- No distinction between active and inactive machine time

- Operator data not integrated

- Calculations not compliant with the NF E 60-182 standard

- Inconsistent results from one workstation to another

💬 Result: approximate KPIs that are impossible to compare or reliably use for decision-making.

A complete, automated calculation of OEE, OOE, and TEEP

JITbase collects machine signals and operator inputs. Based on defined work shifts, breakdowns, and preventive maintenance, the software automatically calculates performance indicators in compliance with the NF E 60-182 standard:

✅ TEEP (Total Effective Equipment Performance) — based on total time

✅ OOE (Overall Operations Effectiveness) — based on operating time

✅ OEE (Overall Equipment Effectiveness) — based on required time

✅ Detailed loss breakdown — availability, performance, and quality

💡 One single source of truth for all your industrial performance.

How it works?

1️⃣ Machine activity time, performance, and quality data are collected directly from machines or through the operator interface

2️⃣ Shift openings and their reasons (breakdowns, preventive maintenance, vacations, etc.) are defined in the production schedule

3️⃣ JITbase automatically applies the NF E 60-182 standard formulas to calculate OEE, OOE, and TEEP

4️⃣ All three indicators can be analyzed through reports and real-time dashboards.

Everything is calculated automatically, directly in JITbase.

Why it matters?

A reliable, standardized OEE calculation is essential to truly understand your performance level and your capacity to increase productivity.

Learn more: OEE, OOE, and TEEP — the essential production performance indicators

With JITbase:

✅ Comparable indicators across plants, for every machine or workstation

✅ Full visibility into real losses and improvement opportunities

✅ A reliable measurement of overall factory performance

💬 An OEE that is consistent, actionable, and fully aligned with industry standards.

Customer Example

“We used to calculate OEE in our ERP, based on operator clocking, which led to inaccurate results.

JITbase standardized our approach. We finally speak the same performance language and clearly understand our real improvement opportunities.”

— Marco, Production Director, aerospace machining shop

Pro Tip

✅ OEE only makes sense when the calculation is complete and standardized.

✅ Depending on what you want to improve, it may be more relevant to analyze OEE, OOE, or TEEP.

The NF E 60-182 standard enables performance indicators to be compared on a common, consistent basis. JITbase automates its application — with no extra effort.

Move to a complete OEE with JITbase

Measure the true performance of your operations — automatically, in real time, and in full compliance with recognized industry standards.