Optimize your operators’ time — automate workload balancing in real time.

Know where every operator should be, when, and why — without whiteboards or guesswork.

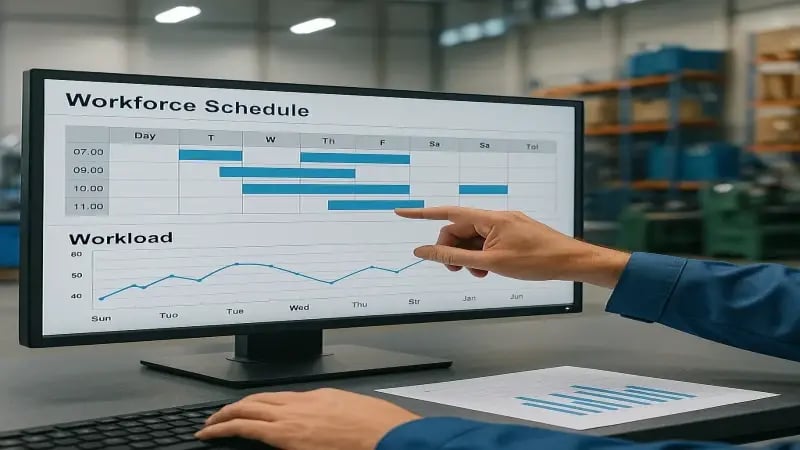

You can’t balance workloads if you can’t see them.

Supervisors often manage 10 to 20 machines and several operators — all manually.

Without real-time visibility, they don’t know:

- Which operator is overloaded or underused

- When a machine will stop and need attention

- How to assign tasks efficiently

Result: constant stress, lost time, and uneven workloads.

💬 And in a context of machinist shortage, every minute counts.

Balance operator workloads in real time.

JITbase automatically calculates the optimal allocation of operators on your machines,

based on live production data, shift schedules, and machine status.

Key features:

✅ Automatic workload calculation per operator

✅ Real-time view of who’s doing what

✅ Smart alerts when a machine will stop soon

✅ Operator reallocation suggestions

✅ Integration with live machine and planning data.

💬 Supervisors stay in control — without spreadsheets or guesswork.

More machines per operator, less stress, and more control.

With JITbase OPS, shops typically achieve:

- +20% more machines operated per person

- Fewer production interruptions

- Immediate detection of operator overloads

- Better use of human resources

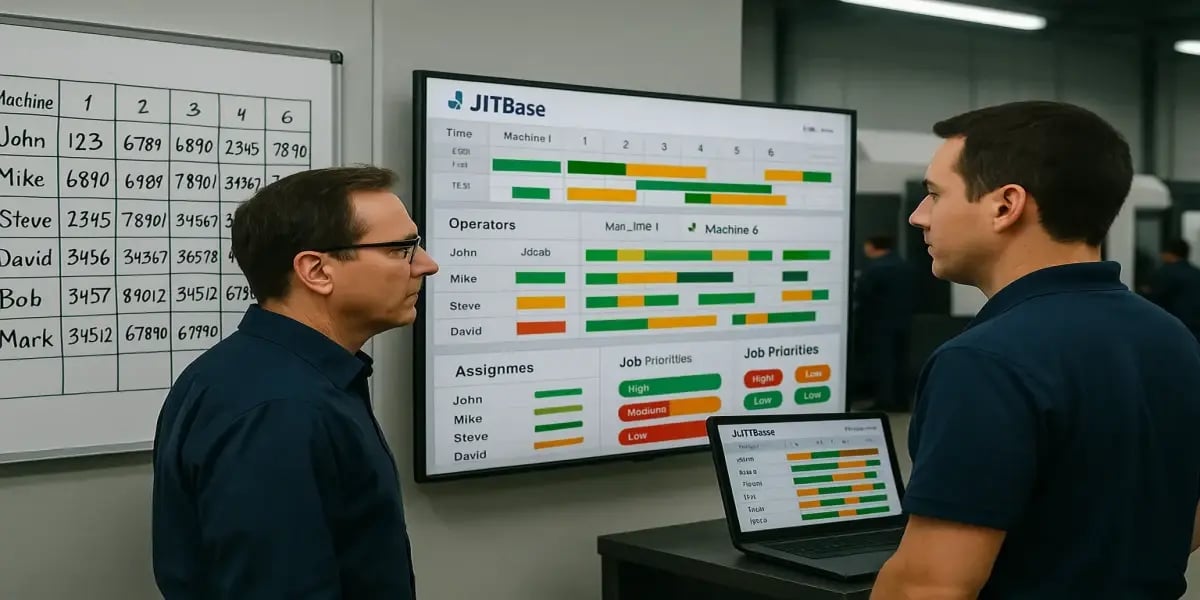

Goodbye whiteboard — hello live visibility.

Each operator sees directly:

- Which machines they’re responsible for

- When a machine will soon stop

- Which job will require their next intervention

Supervisors, in turn, see the entire team’s workload in real time — no need to walk the floor or make calls.

Works seamlessly with Planning and Machine Monitoring.

JITbase OPS connects automatically to your existing data:

- From the Production Planning module for active jobs and schedules

- From Machine Monitoring for real-time machine status

- From shift calendars and operator clocks for availability

💡 One ecosystem — one source of truth for your team allocation.

We finally know exactly where to send each operator — no more whiteboard chaos.

“Before JITbase, we spent 30 minutes every morning updating who goes where.

Now, the system updates itself as the day evolves.”

— Production Supervisor, Aerospace supplier

Start small. Scale across your team.

Try it with one shift or one department.

Then expand to the full shop once you see the impact.