Total visibility on your shop floor, beyond the machines

With the new JITbase Operator Interface, you can now track all production activities — machining, assembly, inspection, deburring, and other manual tasks — in a single, connected system.

Half of your production is invisible

Most monitoring systems stop at CNC machines.

Yet 30–40% of total production time comes from manual work:

❌ Assembly and adjustments

❌ Quality inspections

❌ Deburring, cleaning, setup

❌ Small manual tasks between cycles

💬 This invisible part of the process often goes untracked and unmanaged.

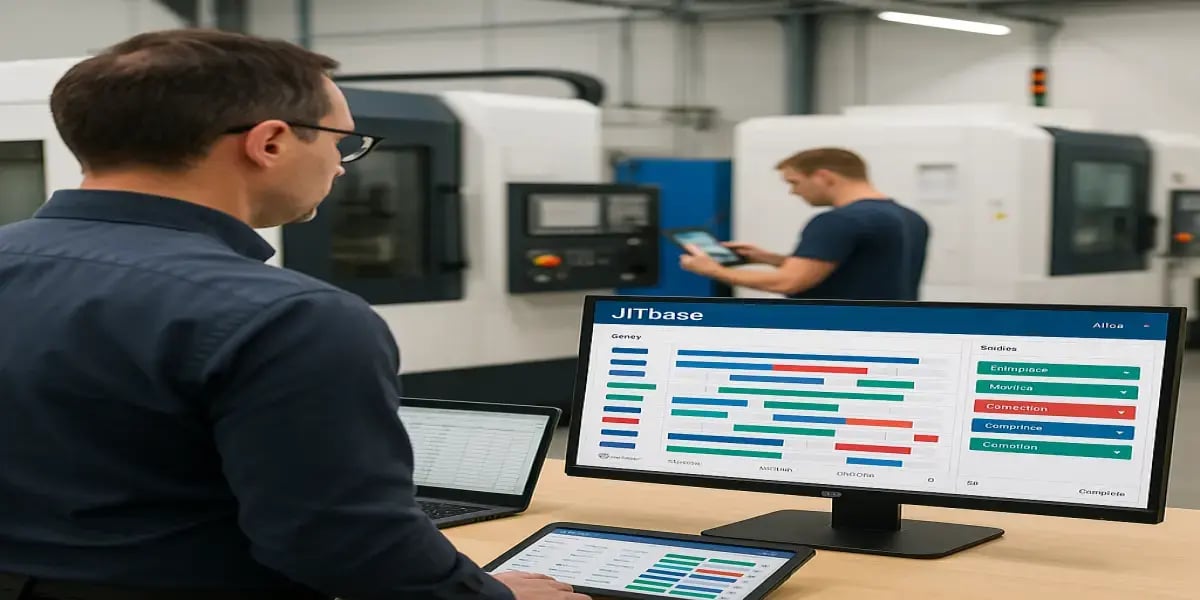

One simple interface for all operations.

The JITbase Operator Interface lets every operator view and report their tasks —whether manual or automated — directly from their workstation.

All data is synced in real time with the production plan and performance reports.

✅ Track manual operations like assembly, inspection, or maintenance

✅ Automatic time capture for each task

✅ Real-time communication with supervisors

✅ Full traceability of every job on the floor.

💡 Digital transformation is complete only when it includes the human side.

How it works?

Each workstation is equipped with a simple screen (PC, tablet, or terminal).

Operators can see:

-

Upcoming jobs and priorities

-

Assigned tasks and current status (in progress, completed, pending)

-

Comments, alerts, or quality notes

Every action updates the live schedule and OEE reports automatically —

no manual data entry required.

Why it matters

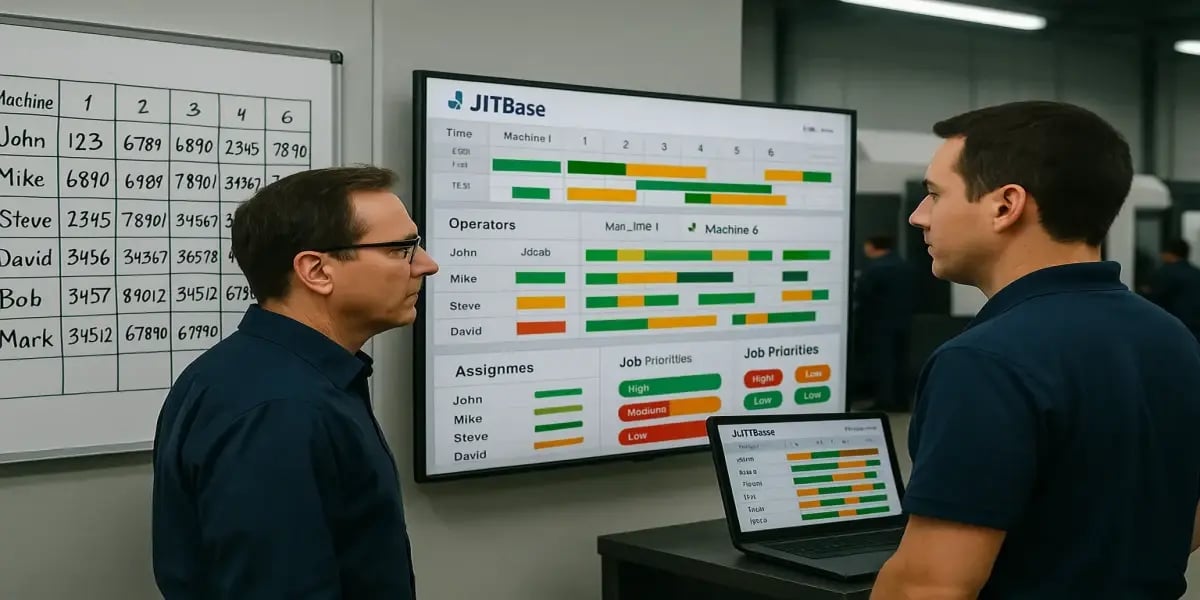

Manual operations are a critical part of production flow.

Without visibility, it’s impossible to manage workload, bottlenecks, or true efficiency.

With JITbase:

✅ Human work becomes visible and measurable

✅ Supervisors see the full picture, not just machine data

✅ Overall performance (OEE/Availability) finally reflects reality.

💬 You’re not just monitoring your machines — you’re managing your entire shop floor.

Pro Tip

✅ Machine performance only makes sense when human performance is visible too.

Manual work isn’t an exception — it’s part of the process.

JITbase makes it measurable, connected, and actionable.

Try the JITbase Operator Interface

Track your entire production — machines and manual tasks — in one simple tool.

No complex setup. No additional hardware.