Your ERP stores the data. JITbase brings it to life.

Connect your existing scan systems and get live planning and shopfloor dashboards in less than 48 hours – no sensors, no manual input, no disruption.

You already have the data. But you don't use it.

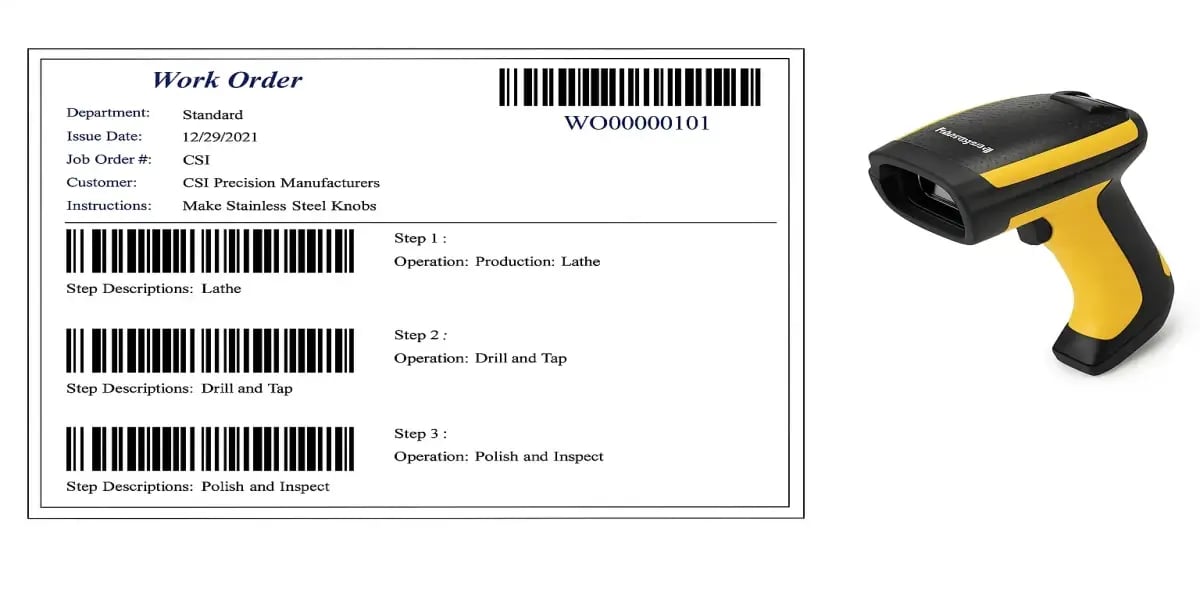

Your operators already scan parts, jobs, and completed quantities.

But all this data ends up locked in your ERP, never visible to the people who need it most — your production teams.

The result:

❌ The production plan is updated manually.

❌ Supervisors can’t see live progress or delays.

❌ Operators discover problems too late.

Your ERP records everything… but no one sees it move.

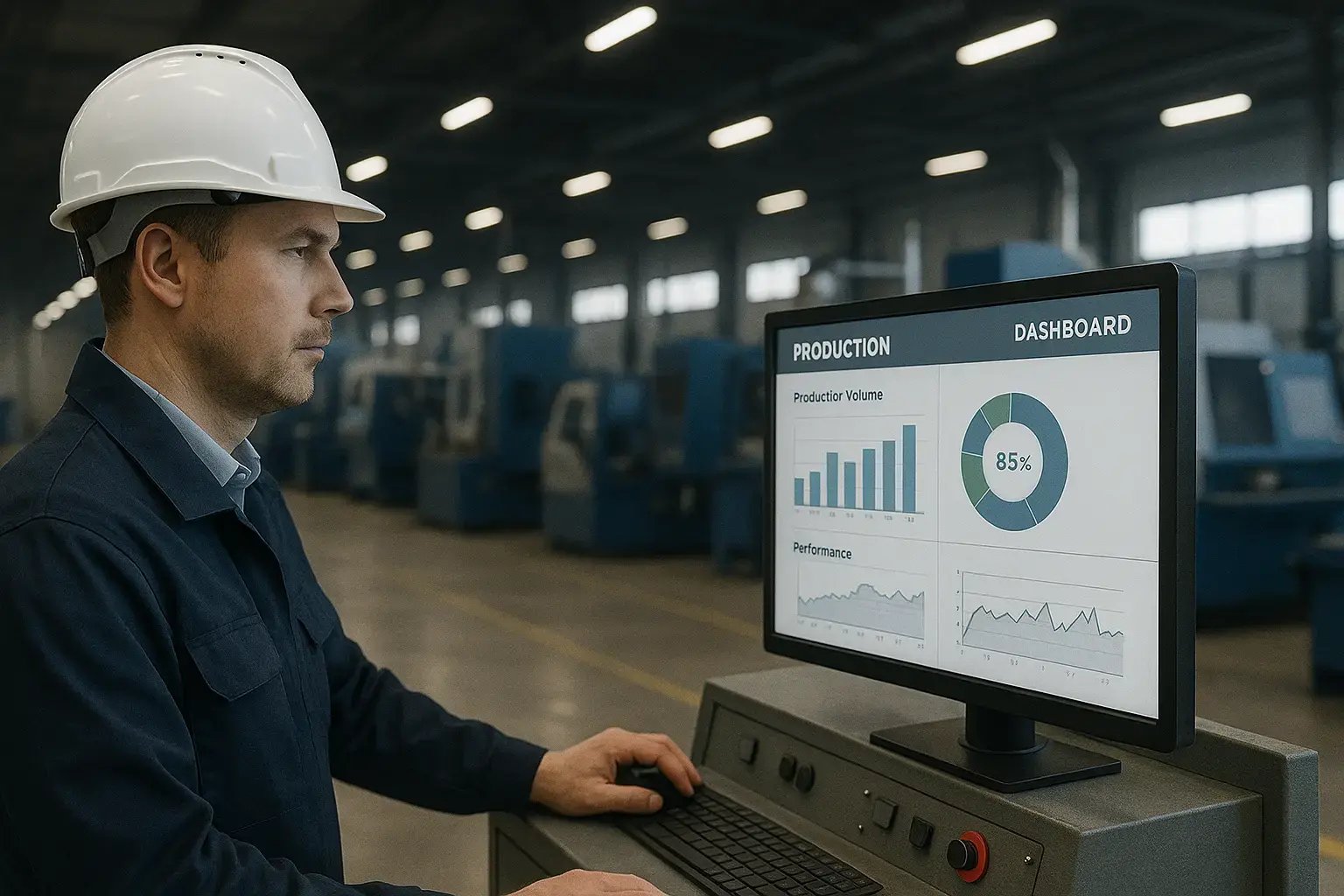

JITbase turns your ERP data into a live action plan.

By simply using the data generated by your operator scans, JITbase gives you visibility you need to properly manage production.

In just a few hours, you can see:

✅ The live progress of each job and machine

✅ Automatic updates of priorities and delays

✅ Live Dashboard with Setup, Production, Maintenance updates

✅ Real-time job completion and delivery forecasts

All this without changing your processes or adding a single sensor.

Live production planning — ready in 48 hours

With your existing data from your operator scans, JITbase provides you with:

-

Dynamic scheduling board – jobs and progress updated automatically

-

Shopfloor communication screens – operators see priorities in real time

-

Performance analytics – track efficiency, delays, and workloads

No IT project. No long integration. No extra effort.

Just visibility, control, and speed — in 48 hours.

Testimonial

“Our operators were already scanning everything, but no one could see what was happening on the shop floor.

With JITbase, we had live dashboards up and running within the first week. We stopped planning in the dark.”

— Daniel, Operations Manager in a machine shop

Leverage the data from your scans you already have!

JITbase connects to your existing systems and turns static ERP data into live, actionable production visibility.

In less than 48 hours, you’ll see your real progress — without changing a thing on the shop floor.