How One Aerospace Shop Increased CNC Utilization by 25%

Problem & Context

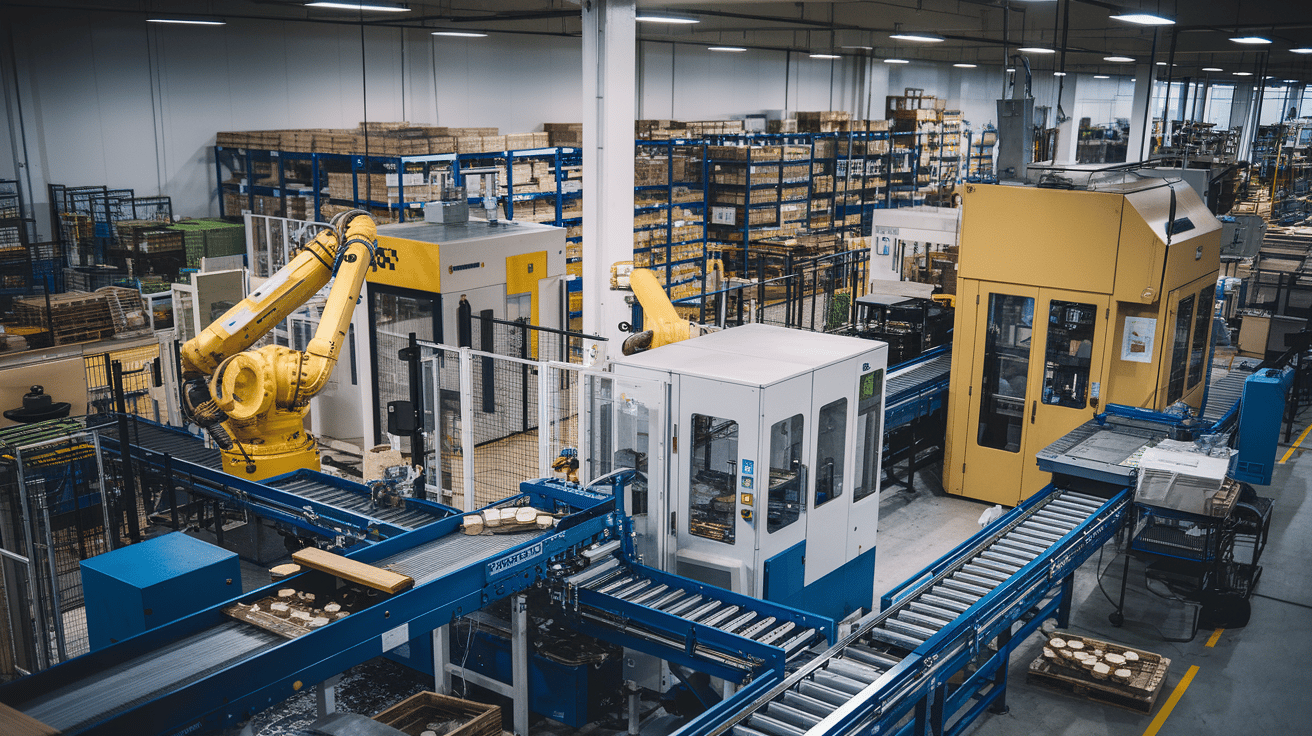

Leesta, a jet engine part manufacturer, faced a major issue: not enough skilled operators to keep machines running. With rising demand and limited resources, they needed a smarter approach to boost productivity without adding headcount.

By shifting to a system where one operator manages more machines, with real-time alerts and optimized task sequencing, they transformed their shopfloor operations.

Results That Matter

After deploying JITbase’s Live Guidance:

- Machine uptime jumped from 51% to 64%

- Operators confidently managed 3 machines instead of 2

- Stress levels dropped, and decisions were data-driven

The results? More output. Fewer delays. And real ROI in less than a shift.

Learn How They Did It And How You Can Too

Download the case study to see the exact process and results from Leesta.If you’re onboarding with JITbase now, this is your blueprint to getting quick wins with minimal effort.

Get rid of Excel for production planning

Equip your Supervisors and Production Managers with the tools they deserve