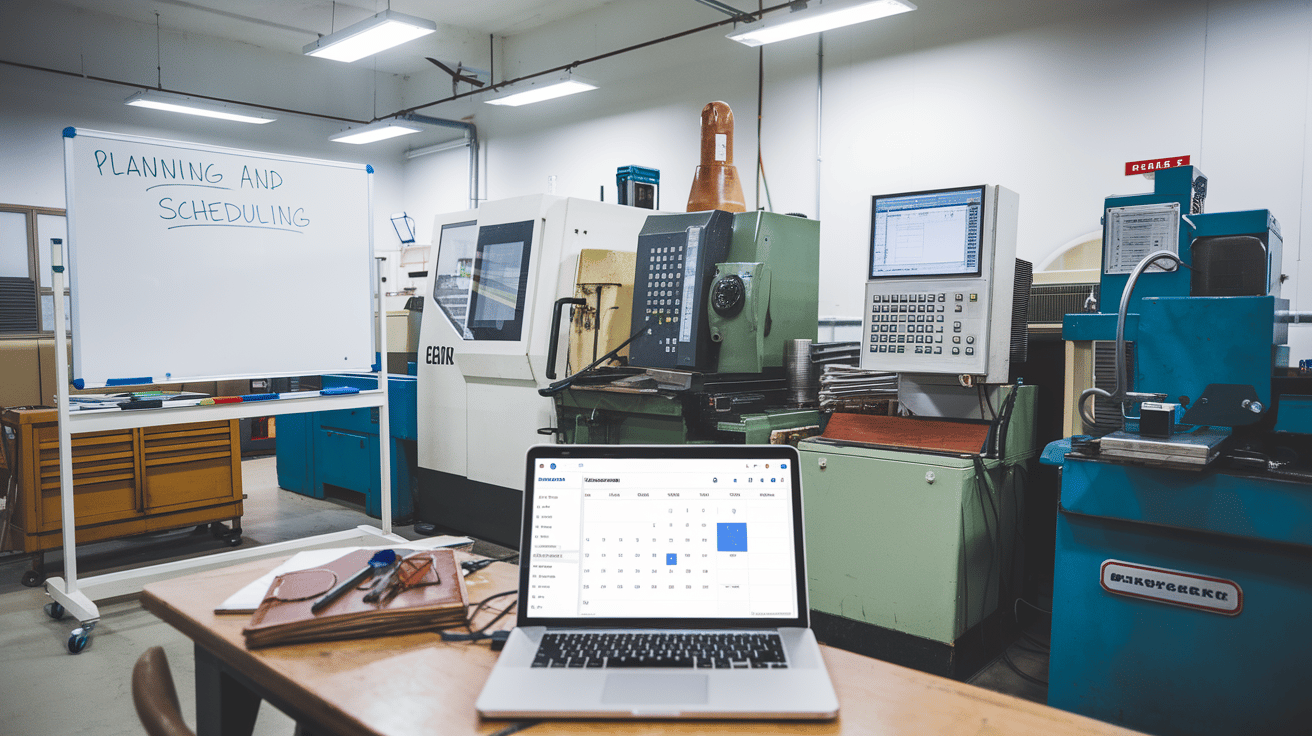

Production Planning should not be done in Excel

Dynamic Scheduling Made Easy

Track work orders and operations in a tool designed for production tracking. Build the backlog of operations by machine easily with drag & drop capability and update the plan as needed during the shift.

CNC shops using JITbase are seeing clear, measurable benefits. Whether you're a high-mix, low-volume job shop or a high-output production facility, connecting planning to machine data leads to real operational improvements.

.webp?width=452&height=253&name=uX3c7jr6QW2X7eb8HCMxgQ%20(1).webp)

Live Communication to Operators

Improve the communication between the office and the shop floor. Operators visualize the machine allocation and jobs they have to perform on a live dashboard. Any update to the plan is refreshed in real time.

Workforce management becomes proactive not reactive. Instead of chasing problems all day, you’re allocating resources intelligently and avoiding burnout or inefficiency.

Benefits of Effective Manufacturing Scheduling

- On-Time Delivery

- Increased Efficiency

- Cost Savings

- Enhanced Customer Satisfaction

Supervisors now adjust in real-time, not hours later. Schedules stay relevant from shift to shift. And instead of firefighting, production teams can actually optimize.

Get rid of Excel for production planning

Equip your Supervisors and Production Managers with the tools they deserve