How Smarter CNC Programming Saved $700K

Problem & Context

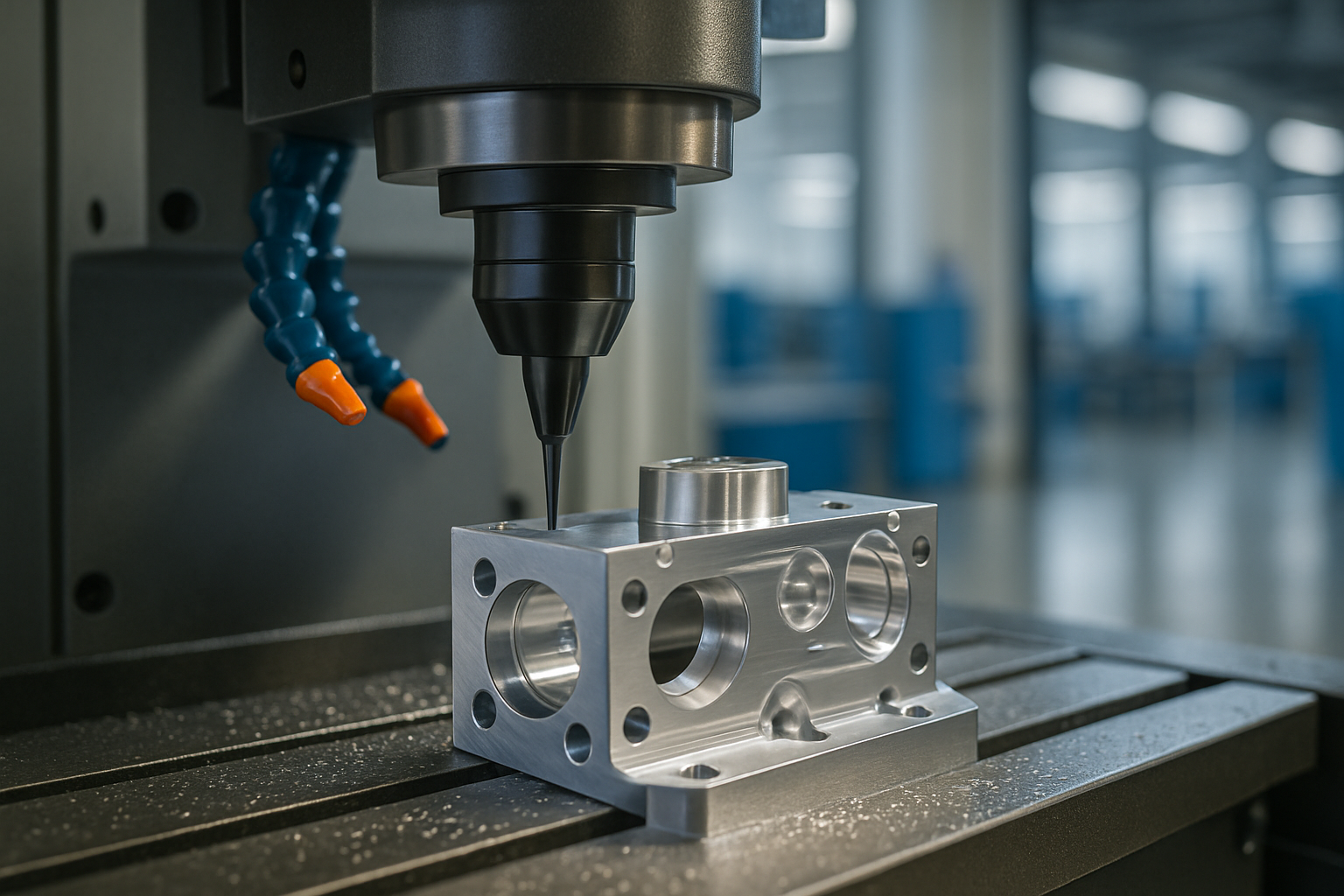

Leesta faced a common issue in CNC shops: too many manual interventions (M00s) interrupting programs. Operators were overused, and machines couldn’t run autonomously for long.

Using JITbase, they identified and removed unnecessary M00s based on operator behavior and real-time machine data, without compromising process quality.

Results That Matter

After improvement:

- Some programs went from 9 planned stops to just 3

- Autonomous machining time increased from 7 to 28+ minutes

- Total program time was reduced by up to 19%

With longer lights-out windows, operators managed more machines, improving OEE by 4%, translating to $700,000 in annual savings.

See the Programs. See the Numbers

This case study includes real program before/after examples, with exact time savings and manual workload reductions.

If you want to reduce cycle time and unlock more operator bandwidth, this download is a must-read.

Get rid of Excel for production planning

Equip your Supervisors and Production Managers with the tools they deserve