Introduction

The manufacturing industry is entering a pivotal moment in its evolution. Global competition, rising customer expectations, workforce shortages, and increasing operational complexity are putting tremendous pressure on factories to operate more intelligently and more efficiently. Traditional methods of workforce management (manual tracking, verbal communication, paper instructions, and delayed reporting) are no longer sufficient to meet modern production demands.

This is where the Connected Worker emerges as a critical pillar of the future of manufacturing.

Far from being a buzzword, it represents a structural shift in how operators, machines, and data interact on the shop floor. By equipping workers with digital tools, real-time information, and integrated workflows, manufacturers can create a more resilient, efficient, and high-performing workforce.

This article explores how the Connected Worker model is transforming workforce management, what benefits it brings, and how manufacturers can prepare for the next generation of smart, data-driven operations.

What Is a Connected Worker? A Modern Vision of Workforce Empowerment

A Connected Worker is an operator who interacts with digital systems that provide real-time insights, task guidance, and operational coordination. Instead of relying on static paper documents, outdated spreadsheets, or inconsistent verbal updates, Connected Workers use:

- digital work instructions

- operator terminals or tablets

- mobile apps

- IoT-enabled machine data

- real-time dashboards

- automated alerts

- digital task lists

- communication interfaces.

The result is a digitally enhanced work environment where operators, machines, and supervisors always remain synchronized.

This model doesn’t replace operators, it amplifies their capabilities.

By eliminating guesswork, improving knowledge access, and streamlining communication, the Connected Worker becomes a key enabler of operational excellence.

1. Real-Time Data: From Reactive to Predictive Workforce Management

Manufacturing operations run on information but the timing, accuracy, and accessibility of that information fundamentally determine performance. Historically, the production floor has relied heavily on manual reporting, delayed updates, or paper logs to understand what truly happens in real time.

This leads to serious challenges:

- downtime is discovered after it happens

- operators waste time checking machines manually

- supervisors react hours too late

- small issues grow into major disruptions

- planning becomes detached from reality

- teams operate in the dark.

The Connected Worker model transforms this dynamic through real-time visibility.

With digital dashboards and IoT data, operators can:

- view machine status instantly

- identify performance drops

- track cycle completion

- detect anomalies before escalation

- validate instructions

- reduce non-value-added checks.

Instead of navigating uncertainty, operators confidently execute tasks with accurate information.

b- Supervisor-Level Insights for Strategic Decisions

Supervisors benefit just as much. Real-time visibility allows them to:

- balance workloads

- reassign operators quickly

- detect bottlenecks

- resolve delays earlier

- coordinate more effectively

- maintain production flow.

Instead of waiting for end-of-shift summaries, they gain a live snapshot of the entire operation.

2- Empowering Operators With Digital Tools and Smart Guidance

Operators are central to manufacturing success, yet they often carry an excessive administrative burden:

- tracking tasks manually

- reporting progress

- searching for instructions

- walking to find supervisors

- guessing priorities.

The Connected Worker model aims to eliminate this friction.

a- Clear Digital Work Instructions

Digital instructions provide:

- consistent procedures

- updated documentation

- step-by-step guidance

- embedded quality checks

- easy access to knowledge.

This is especially valuable in environments with frequent changeovers, mixed product lines, or high operator turnover.

b- Dynamic Task Prioritization Based on Real Conditions

Connected Worker tools automatically adjust task priorities based on:

- machine performance

- real-time alerts

- scheduling constraints

- material availability

- urgent requests.

Operators no longer wonder what to do next, the system guides them to the highest-value action.

c- Skill Development and Knowledge Retention

Because knowledge is digitized and accessible, operators:

- onboard faster

- learn new tasks with less supervision

- reduce dependency on tribal knowledge

- perform consistently across shifts.

This improves workforce flexibility and resilience.

3- Streamlined and Automated Communication Across the Shop Floor

Poor communication is one of the biggest sources of waste in manufacturing.

Disconnected systems, unclear expectations, and delayed messages all contribute to inefficiencies.

The Connected Worker ecosystem centralizes communication into a unified digital platform.

a- Examples of Communication Breakdowns (Traditional)

- maintenance discovers a machine issue 20 minutes too late

- operators finish a task but the planner is unaware

- quality issues remain unnoticed until the next batch

- supervisors walk across the floor to deliver updates

- priorities shift but operators don’t know.

b- How the Connected Worker Fixes This?

Communication becomes:

- immediate

- automated

- structured

- traceable

- consistent

For example:

- When a machine stops, maintenance receives an automatic alert.

- When an operator completes a task, JITbase or another system updates the plan instantly.

- When priorities shift, all affected operators see the change in real time.

This reduces delays, eliminates confusion, and accelerates decision-making.

4- Smarter Resource Allocation With Data-Driven Insights

One of the most powerful advantages of the Connected Worker approach is optimized resource allocation.

Assigning the right operator to the right machine at the right time is complex because conditions change constantly:

- unexpected downtime

- absenteeism

- shifting deadlines

- machine constraints

- operator skill variations.

Connected Worker systems integrate all these variables to support smarter decisions.

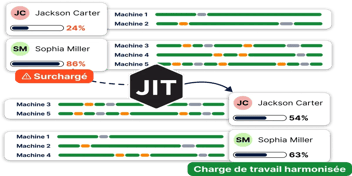

a- Balancing Workloads and Avoiding Overload

Real-time visibility allows managers to:

- balance workloads between operators

- prevent bottlenecks

- reduce operator overload

- optimize the use of multi-skilled workers.

This leads to better throughput and healthier work conditions.

b- Predictive Workforce Management

Thanks to data from machines and operators, Connected Worker tools can anticipate:

- which stations will require help

- when workloads will exceed capacity

- when operators will need support

- how future planning decisions will impact flow.

These predictive insights enable manufacturers to avoid disruptions rather than react to them.

Workforce Management platforms combine real-time machine data with operator allocation to recommend optimal assignments and highlight workforce constraints before they affect production.

5. Supporting the Transition Toward Industry 4.0

Industry 4.0, the era of smart factories, relies on deep integration between automation, IoT, analytics, and human expertise. The Connected Worker is a key bridge between these elements.

a- More Reliable Data for AI and Automation

Connected Worker systems produce clean, structured data that enhances:

- predictive maintenance

- automated scheduling

- machine learning models

- OEE improvement initiatives

- quality control algorithms.

The better data coming from humans and machines, the more effective these systems become.

b- Smoother Technology Adoption

When operators are digitally equipped, factories can implement new technologies with less resistance and fewer disruptions.

Connected Worker systems reduce the “technology gap” between older workflows and modern automated environments.

6. Enhancing Safety, Focus, and Job Satisfaction

Although it relies on digital tools, the Connected Worker model is deeply human-centric.

a- Reduced Cognitive Overload

Operators often juggle:

- multiple machines

- frequent changeovers

- shifting priorities

- incomplete information.

Digital guidance reduces mental load, allowing operators to focus on execution instead of information hunting.

b- Improved Safety

Digital warnings, instructions, and automatic alerts reduce risks by:

- identifying unsafe conditions early

- standardizing procedures

- reducing errors caused by outdated instructions.

c- Higher Job Satisfaction

When operators have clarity and support, they:

- feel more valued

- perform with more confidence

- experience less stress

- contribute more meaningfully.

The result is a stronger and more engaged workforce.

Why the Connected Worker Matters More Than Ever

Manufacturers today face unprecedented challenges:

- skilled labor shortages

- increasing product complexity

- higher customer expectations

- pressure for shorter lead times

- demand for real-time visibility.

The Connected Worker model addresses these issues by enabling:

- better coordination

- smarter resource allocation

- fewer disruptions

- higher productivity

- safer work environments

- greater operational stability.

For many factories, adopting Connected Worker technologies is no longer optional, it’s essential for maintaining competitiveness.

Conclusion: The Future of Manufacturing Is Connected

The Connected Worker is redefining how factories operate.

By creating environments where people, machines, and data work together seamlessly, manufacturers can achieve:

- greater agility

- better quality

- more predictable workflows

- improved workforce engagement

- stronger competitiveness.

Solutions like JITbase, which combine machine data with operator workflows, help manufacturers bring the Connected Worker vision to life in a practical and scalable way.

Balance and optimize your operators in real time

Learn more