Introduction: Why CAPM Has Become Essential in Modern Manufacturing?

Today’s manufacturers face unprecedented pressure: shorter delivery times, rising customer expectations, fluctuating supply chains, and ongoing labor shortages. To stay competitive, companies must rely on systems that provide accurate, reliable, real-time control over production.

Enter CAPM (Computer-Aided Production Management): a modern production planning and control tool that synchronizes machines, operators, workflows, and materials. CAPM bridges the gap between ERP planning and real shop-floor execution, ensuring a fast, stable, and predictable manufacturing flow.

In the era of Industry 4.0, CAPM is no longer a “nice-to-have.” It is becoming a cornerstone for operational excellence, helping factories increase productivity, reduce waste, and better manage complexity.

This article explains how CAPM transforms production management, the benefits it delivers, and how manufacturers can leverage it to build a more efficient, agile, and resilient production chain.

1. What Is CAPM? A Planning Tool at the Center of Industrial Operations

CAPM is a software-based production management system designed to plan, organize, monitor, and optimize manufacturing processes. It centralizes all operational data and coordinates machines, operators, materials, and workflows.

1.1. Complete visibility across all production processes

CAPM provides a real-time view of the entire production chain, including:

- work orders,

- routings and BOMs,

- machine loads and available capacities,

- operator schedules and skill sets,

- supplier and material lead times,

- customer delivery priorities.

This holistic visibility enables planners to make informed decisions and quickly detect issues before they become disruptions.

1.2. Planning software designed specifically for manufacturing

Unlike spreadsheets, legacy tools, or generic scheduling apps, CAPM is built for industrial environments and integrates:

- machine sequencing constraints,

- changeover times,

- setup and tooling requirements,

- resource calendars,

- maintenance planning,

- priority-based scheduling.

It becomes a vital link between the ERP’s theoretical plan and the shop floor’s real-world conditions.

1.3. Aligning digital and physical workflows

CAPM synchronizes production planning with execution, reducing:

- bottlenecks,

- quality issues,

- delays,

- unnecessary work-in-process (WIP).

When operators, planners, and supervisors work from the same data, the entire supply chain becomes more predictable and efficient.

2. Key Benefits of CAPM for Modern Production Environments

Deploying a CAPM solution brings measurable improvements across productivity, communication, planning accuracy, and resource usage.

2.1. More accurate and reliable scheduling

Poor planning often leads to:

- late orders,

- overtime,

- low machine utilization,

- emergency purchasing,

- quality defects.

CAPM solves these problems by offering:

- accurate, standardized cycle times,

- automatic constraint-based scheduling,

- real-time updates of workloads and capacities,

- “what-if” simulations to test scenarios.

Planners gain a clear, reliable, and actionable view of the production timeline.

2.2. Better utilization of machines and operators

One of the strongest advantages of CAPM is its ability to optimize critical resources.

Machines

- fewer idle periods,

- reduction of micro-stops,

- improved sequencing and changeover planning,

- early detection of capacity overload,

- better alignment with maintenance windows.

Operators

- tasks assigned based on skills and priorities,

- reduced walking time,

- improved coordination,

- clearer priorities at each workstation,

- increased autonomy through real-time data.

This leads to higher throughput and a more efficient shop floor.

2.3. Smoother and more predictable production flow

CAPM creates a more stable production environment by anticipating:

- bottlenecks,

- shortages of materials or labor,

- urgent or last-minute orders,

- machine breakdowns,

- delays from suppliers.

With these insights, companies can maintain agility even in high-mix, low-volume environments.

2.4. Measurable improvements across performance KPIs

Manufacturers using CAPM typically observe:

- 10–30% productivity gains,

- 30–50% fewer late deliveries,

- 15–25% improvement in OEE,

- reduction in emergency purchasing and rework,

- better cross-functional communication.

CAPM becomes a strategic enabler of competitiveness.

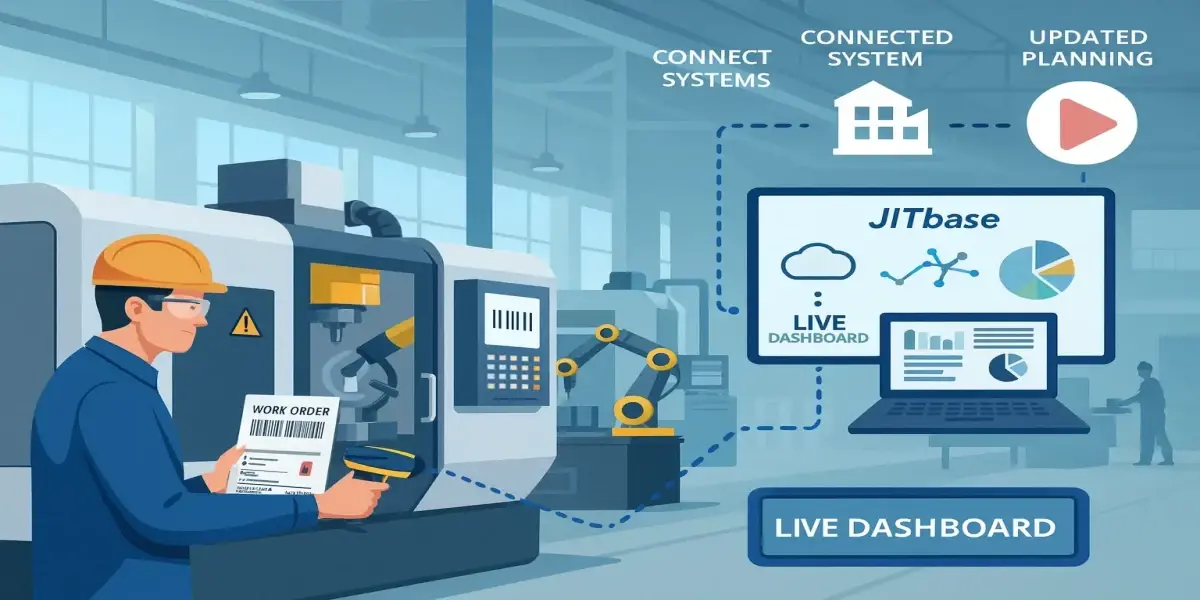

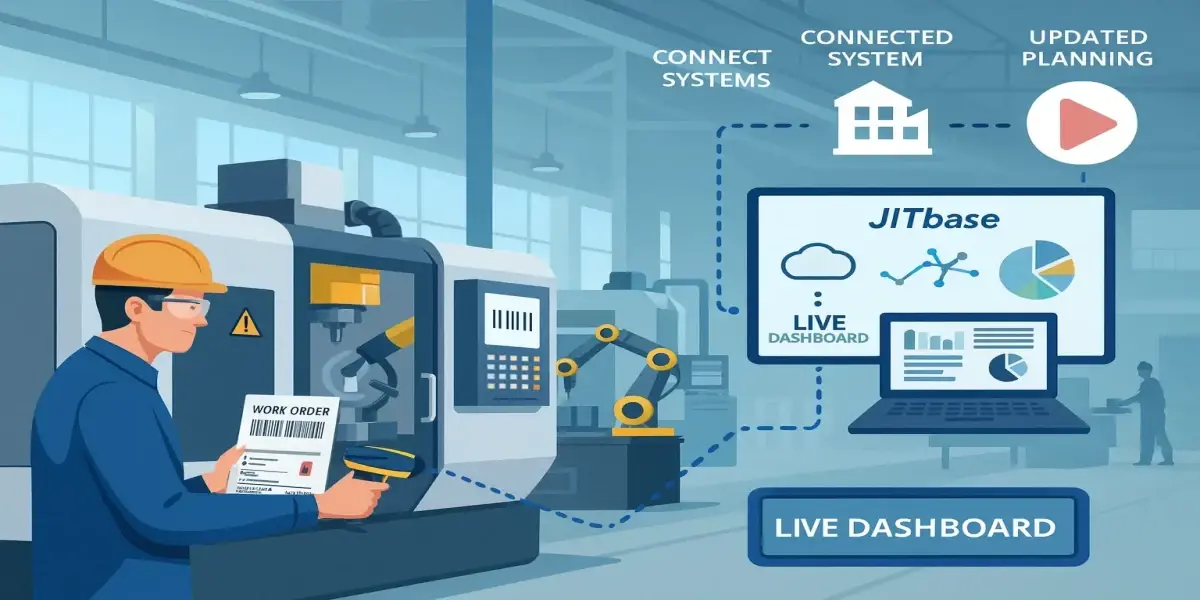

3. CAPM and Industry 4.0: Toward a Connected and Smarter Production Chain

When CAPM integrates with modern Industry 4.0 technologies, its impact increases dramatically.

3.1. Machine connectivity: real-time shop-floor data

By connecting CNC machines, sensors, and IoT devices to CAPM, manufacturers can collect real-time data such as:

- machine status (running, stopped, setup),

- cycle times and completed units,

- downtime details,

- operator interactions,

- alerts and quality checks.

This enables:

- immediate replanning,

- precision capacity forecasting,

- accurate lead-time calculations,

- instant priority updates,

- reduction of planning/execution mismatches.

Real shop-floor events are reflected instantly in the schedule — a major leap for operational reliability.

3.2. ERP integration for end-to-end digital continuity

CAPM creates a seamless information flow between:

- ERP (sales, purchasing, inventory),

- CAPM (planning and scheduling),

- MES/IoT (real-time execution tracking).

This continuity improves:

- traceability,

- data reliability,

- inventory accuracy,

- customer service levels,

- decision making.

The entire factory becomes more synchronized.

3.3. Greater agility and resilience

CAPM helps manufacturers adapt faster to:

- demand variability,

- supply chain disruptions,

- operator shortages,

- equipment downtime,

- product mix fluctuations.

It supports an agile production model capable of absorbing shocks without sacrificing performance.

4. How to Choose the Right CAPM Tool for Your Factory

Not all CAPM systems deliver the same value. Here are the most important selection criteria.

4.1. Ease of use

A powerful system is useless if planners and operators cannot use it daily.

The best CAPM tools are:

- intuitive,

- user-friendly,

- visually clear,

- easy to learn.

High user adoption = high data reliability.

4.2. Integration capabilities

A modern CAPM solution should interface seamlessly with:

- ERP systems (SAP, Oracle, Microsoft, Sage, Epicor, Infor),

- machine data platforms,

- IoT sensors,

- quality systems,

- cloud platforms.

Interoperability is essential for digital transformation.

4.3. Real-time execution tracking

A planning tool without real-time execution is not enough.

Modern CAPM must include:

- machine dashboards,

- OEE tracking,

- downtime analytics,

- operator feedback tools,

- automatic rescheduling.

This creates a continuous loop of improvement.

4.4. Scalability and cost efficiency

The ideal CAPM system should be:

- modular,

- scalable,

- cost-effective,

- quick to deploy,

- adaptable to your production complexity.

Lightweight, cloud-based CAPM systems are becoming increasingly popular for these reasons.

5. Why CAPM Has Become a Strategic Lever for Industrial Organizations

CAPM impacts far more than the production department. It benefits:

- operations management,

- supply chain,

- purchasing,

- quality control,

- maintenance,

- customer service,

- strategic leadership.

With reliable, centralized data, companies make faster and smarter decisions — at every level.

Conclusion: CAPM as a Cornerstone of Modern Manufacturing Performance

In today’s manufacturing landscape, precision, visibility, and agility are no longer optional.

CAPM provides all three.

By combining:

- real-time data,

- optimized planning,

- automated workflows,

- connected machines,

- integrated digital systems,

CAPM reshapes how factories operate and drives measurable performance gains.

As Industry 4.0 continues to grow, CAPM becomes more than just a planning tool — it becomes a strategic competitive advantage.