Introduction

In the modern industrial era, global competition, labor shortages, and rising energy costs are putting immense pressure on manufacturing and logistics organizations. Operational leaders must not only achieve higher productivity but also comply with stricter labor regulations and sustainability standards. At the same time, the growing need for agility and data transparency has accelerated the adoption of digital tools that connect the workforce to real-time production insights.

A Labor Management System (LMS) stands at the intersection of technology and human capital management. It provides decision-makers with a comprehensive platform to track, analyze, and optimize labor performance. By combining data analytics, automation, and human oversight, an LMS helps industrial companies strike the right balance between efficiency and employee engagement. This article explores the top five benefits of implementing a Labor Management System and explains how it supports operational excellence, cost reduction, and workforce satisfaction within an Industry 4.0 environment.

1. Enhanced Workforce Productivity

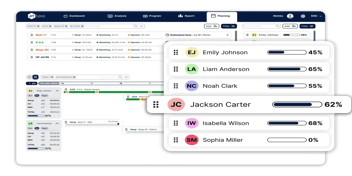

Productivity is the cornerstone of competitiveness in any industrial operation. An LMS provides visibility into how time, labor, and machines interact, allowing managers to pinpoint inefficiencies before they escalate. The system tracks key metrics such as cycle time, takt time, and Overall Equipment Effectiveness (OEE), giving decision-makers precise insights into where to focus improvement efforts.

Key capabilities include:

- Real-time dashboards that display task progress, downtime, and throughput.

- Data-driven performance reviews that promote accountability and continuous improvement.

- Smart automation that aligns tasks with available operators based on competency and workload.

For instance, in an automotive assembly plant, an LMS can detect that certain assembly cells consistently experience longer takt times due to uneven workload distribution. By reassigning tasks and balancing the line, management can boost output without additional labor hours. Over time, these incremental gains translate into higher OEE and better delivery performance.

2. Improved Resource Allocation and Scheduling

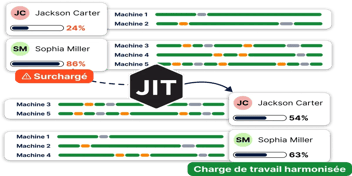

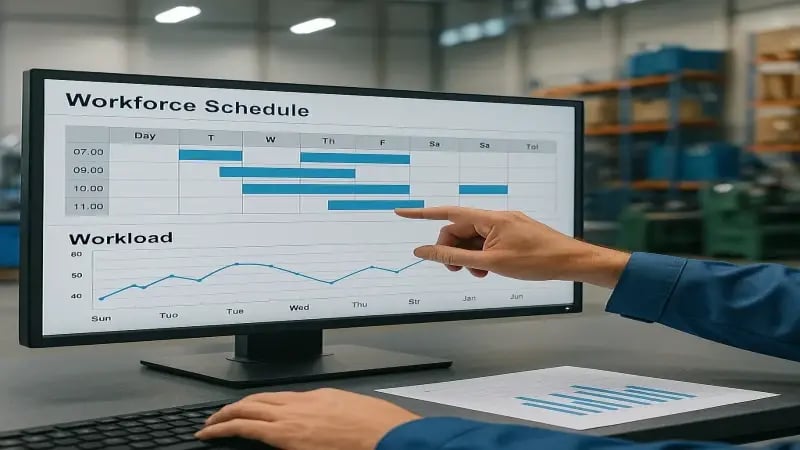

Precise scheduling and balanced resource allocation are critical to avoiding costly production delays or idle labor. An LMS introduces intelligence into workforce planning by integrating labor data with production forecasts, maintenance plans, and customer orders.

Benefits include:

- Dynamic shift management: real-time reallocation of staff during absences, breakdowns, or unexpected orders.

- Skill-based scheduling: ensuring that qualified workers are assigned to complex operations.

- Automated forecasting: predicting staffing needs using historical trends and live demand data.

3. Reduced Labor Costs Through Efficiency and Forecasting

Labor costs typically account for 25–50% of operational expenses in manufacturing and warehousing. By using an LMS, companies gain the ability to reduce these costs systematically without compromising productivity or quality.

Practical cost-saving mechanisms include:

- Overtime optimization: tracking, approving, and forecasting overtime to prevent excessive spending.

- Idle time reduction: automatically identifying underutilized staff and reallocating them to critical areas.

- Predictive analytics: using data to plan labor budgets more accurately and anticipate future workforce needs.

For example, a food processing plant may use LMS data to compare actual labor costs per production line with historical benchmarks. By analyzing discrepancies, managers can identify bottlenecks, improve workflow design, and achieve up to 15% labor cost reduction over time. Additionally, the LMS supports just-in-time (JIT) resource allocation, which minimizes unnecessary payroll expenses while sustaining throughput.

4. Stronger Compliance, Accuracy, and Transparency

Compliance has become a non-negotiable aspect of industrial operations. Labor regulations, union agreements, and occupational safety standards require accurate, traceable reporting. An LMS simplifies compliance by digitizing record-keeping and ensuring that all policies are automatically applied.

Key advantages include:

- Automatic time and attendance tracking, eliminating human error in manual logs.

- Built-in alerts for overtime limits, rest breaks, and legal working hours.

- Seamless payroll and HR integration, ensuring fair and precise compensation.

The transparency offered by an LMS helps prevent disputes over time records or wage calculations. Employees appreciate the fairness of automated tracking, while managers can rely on accurate data during audits or inspections. Moreover, integrating compliance modules helps organizations uphold corporate governance and maintain ISO or ESG certifications.

5. Higher Employee Engagement and Retention

Contrary to the misconception that automation undermines human motivation, a well-implemented LMS fosters engagement and empowerment. By giving employees access to their performance metrics, schedules, and training progress, it promotes ownership and accountability.

Employee engagement benefits include:

- Self-service access to shifts, vacation requests, and productivity metrics.

- Recognition of high-performing employees through data-driven evaluation.

- Balanced workload distribution that reduces stress and turnover.

6. Operational Excellence and Digital Maturity

Implementing an LMS is more than a productivity initiative, it is a step toward digital transformation and long-term resilience. When connected to systems like Manufacturing Execution Systems (MES), Enterprise Resource Planning (ERP), or Internet of Things (IoT) platforms, the LMS becomes part of an integrated ecosystem of operational intelligence.

Strategic advantages include:

- Unified data flow between machines, people, and processes.

- Predictive insights for capacity planning, maintenance, and workforce optimization.

- Standardized KPIs across multiple facilities, supporting benchmarking and global reporting.

For example, a multinational manufacturer integrating LMS and MES platforms gains real-time synchronization between production and labor data. This allows leaders to simulate production scenarios, assess labor demand under different conditions, and continuously refine strategy. Ultimately, digital maturity leads to sustainable operational excellence—where performance, quality, and human potential align.

Ready to advance your shop floor?

Connect Your Machines for Free

JITbase Machine Monitoring – Free for up to 5 machines. Empower your team with real-time data and smarter scheduling today.

Conclusion

For industrial leaders, adopting a Labor Management System is a strategic decision that goes beyond efficiency. It supports a future-ready workforce strategy where transparency, agility, and collaboration drive results. By uniting automation and human intelligence, an LMS enables companies to achieve measurable performance improvements, higher profitability, and stronger employee loyalty.

Solutions such as JITbase demonstrate how modern, data-driven platforms empower manufacturers to bridge the gap between human potential and digital intelligence, helping them build smarter, safer, and more resilient operations aligned with the principles of Industry 4.0.