Introduction

Planning operations on machine tools has become one of the most critical levers for improving industrial performance. With rising customer expectations, complex machining routes, skilled labor shortages, variability in material availability, and tighter deadlines, manufacturers must be able to orchestrate a precise, dynamic, and reliable production schedule to keep their operations under control.

Success rests on three key elements:

- A detailed analysis of the manufacturing process

- A powerful production planning software

- A robust, shop-floor-aware production scheduling strategy

In this expert guide, we’ll walk through a complete approach to strengthening your planning process, optimizing your production plan, reducing downtime, and increasing the productivity of your machine tools.

1. Deeply Understand Your Processes Before You Plan

Effective production planning doesn’t start with a Gantt chart or a spreadsheet. It starts with a clear understanding of how work flows through your shop.

1.1. Map the industrial workflow

A good planning tool must be built on a realistic picture of what happens from raw material to finished part. That means mapping:

- The sequence of machining operations (turning, milling, drilling, grinding, inspection, packing, etc.)

- The interdependencies between machine tools

- Which steps are manual vs. automated

- Real changeover times for each machine

- Actual vs. planned cycle times

- Tooling, fixtures, and setup constraints

This process mapping gives your production planning software the foundation it needs to generate an accurate factory schedule that reflects what’s really happening on the shop floor instead of an idealized version of it.

1.2. Identify bottleneck machines

In many plants, a handful of machine tools create most of the delays:

- A highly utilized 5-axis CNC that every product family touches

- A grinding machine with long cycles and tight tolerances

- A single inspection station that all parts must pass through

These bottlenecks:

- Accumulate long queues

- Generate rush orders

- Amplify any disruption

They must be treated as strategic resources in your production scheduling logic and highlighted clearly on your scheduling board. Your production schedule should be built around protecting and optimizing these bottleneck machines.

1.3. Measure real performance, not assumptions

To build dynamic scheduling, you need real, trustworthy data, not estimates from old routings. Key metrics include:

- Machine utilization rates

- Planned vs. unplanned downtime

- Operator waiting time

- Real changeover durations

- Actual cycle times on each machine tool

- OEE or overall equipment effectiveness

In many CNC shops, actual cycle times differ from theoretical standards by 20 to 40%. Without this visibility, even the best planning logic will generate unrealistic schedules that constantly need to be “fixed” manually.

2. Modernize Your Planning with Production Planning Software

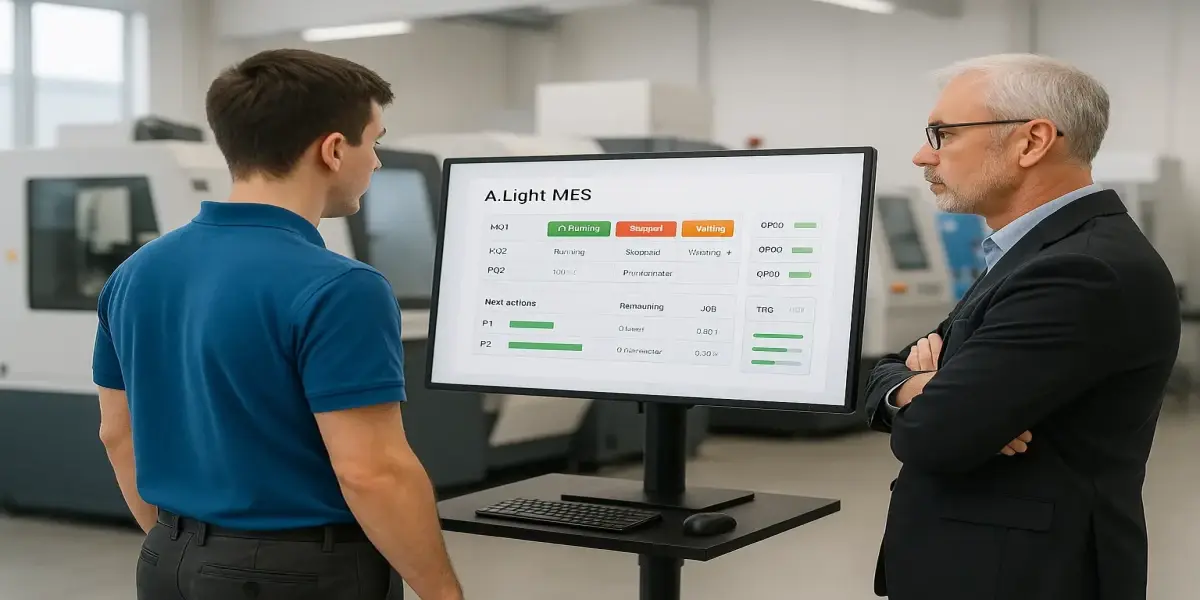

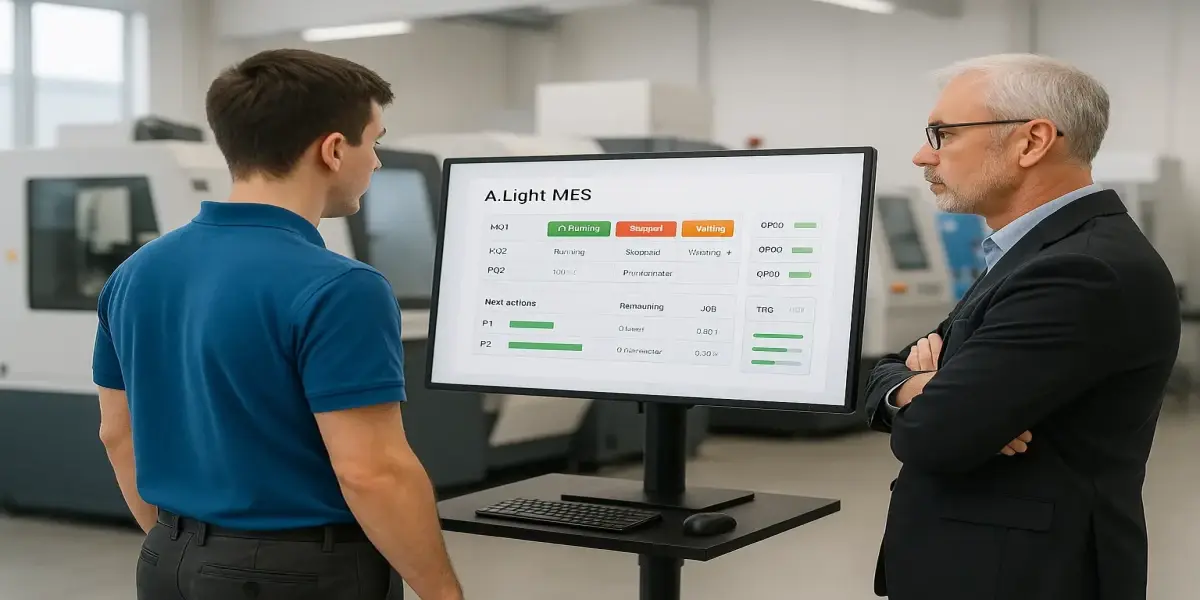

Whiteboards, Excel files, and paper travelers are no longer sufficient to manage modern machining environments. To keep up with complexity and volatility, manufacturers need scheduling software or production planning software that can create, update, and optimize schedules continuously.

2.1. Why production planning software is now essential?

A modern production planning software allows you to:

- Automatically generate a feasible production schedule based on your constraints

- Coordinate workload across machine tools, shifts, and operators

- Visualize your production plan briefly

- Simulate different “what-if” scenarios

- React quickly when something unexpected happens

In just a few seconds, the system can compute a factory schedule that accounts for:

- Machine capacity and availability

- Operator skills and shifts

- Job priorities and due dates

- Setup and changeover times

- Material and tooling constraints

- Maintenance windows

This kind of automation is nearly impossible to reproduce consistently with manual scheduling.

2.2. From static planning to dynamic scheduling

Static planning assumes that things will go according to the original plan. That rarely happens.

With dynamic scheduling, your planning tool is constantly updated in line with what’s really going on:

- A machine breaks down → the production schedule is recalculated

- A rush order appears → the production plan is reprioritized

- A material delivery is late → affected operations are automatically shifted

- An operator calls in sick → the system suggests alternate assignments

This is where automatic scheduling becomes a real advantage: the schedule is not fixed on paper; it is recalculated when conditions change.

2.3. The financial impact of better planning

When a plant adopts a robust production planning software and aligns its manufacturing planning around it, typical results include:

- Up to 20% reduction in downtime

- Around 15% less operator waiting time

- Fewer emergency changes and last-minute rescheduling

- Better utilization of machine tools and cutting tools

- Improved on-time delivery performance

For CNC machining operations, where every minute of spindle time is valuable, the impact can be even greater.

3. Prioritize Operations with a Solid Production Scheduling Strategy

A powerful planning software is not enough on its own. It must be supported by a clear, well-defined production scheduling strategy that matches your business model and constraints.

3.1. Choose appropriate scheduling rules

Common rules include:

- FIFO (First In, First Out) – simple and fair, but not always optimal

- EDD (Earliest Due Date) – prioritizes jobs closest to their due date

- SPT (Shortest Processing Time) – helps reduce average lead time

- Bottleneck-focused scheduling – protects your constraint resources

- Grouping by material or family – reduces changeovers and tool changes

Your scheduling board or digital planning view should clearly reflect the chosen logic, so that everyone understands why jobs are sequenced in a specific order.

3.2. Minimize the impact of changeovers

Changeovers and setups are one of the biggest hidden costs in machining. They can account for up to 30% of lost time if they are not managed deliberately.

To reduce this impact:

- Group similar jobs together to avoid unnecessary tool changes

- Sequence parts by material or program family when possible

- Plan longer setups during off-peak periods or night shifts

- Include realistic setup durations in your production plan, not theoretical ones

When these factors are encoded correctly into your production planning software, the generated production schedule becomes much more realistic and efficient.

3.3. Protect strategic and urgent orders

Not all jobs are equal. Some:

- Belong to key customers

- Are critical for a line-down situation

- Represent prototypes or first-article inspections

- Carry penalties if delivered late

Your planning tool should allow you to flag these jobs and automatically push them up in the production schedule while still respecting constraints and bottlenecks.

4. Integrate People into the Planning Process

No matter how advanced your planning software is, a schedule will fail if it ignores the human side of operations.

4.1. Build a realistic work-hour schedule

A reliable factory schedule is based on a realistic view of available labor:

- Shift patterns (2x8, 3x8, weekend crews, etc.)

- Breaks and handovers

- Vacation, training, and absenteeism

- Operator certifications and machine authorization

This information feeds into daily scheduling and helps create an executable daily production planning view.

4.2. Allocate work based on skills

In a machine shop, one operator may:

- Only be able to run one machine, or

- Be qualified to operate three or four different CNCs

A plant that uses skill-based production scheduling can:

- Better balance workload,

- React faster to unexpected absences,

- Increase flexibility without over-hiring,

- Improve quality by assigning tasks to the right people.

Skill matrices should be integrated into your production planning software, so that the production schedule reflects both machine and human constraints.

4.3. Communicate the schedule clearly

A great production plan that exists only in the planner’s laptop is not enough. The schedule must be:

- Visible

- Understandable

- Accessible in real time

This can be done through:

- Large screens on the shop floor

- Tablets or mobile devices for supervisors and team leads

- Operator terminals showing current and next jobs

When everyone sees the same production schedule, confusion and misalignment drop dramatically.

5. Make Flexibility a Built-In Feature of Your Schedule

In real life, there will always be:

- Machine breakdowns

- Late material deliveries

- Urgent customer requests

- Quality issues

- Last-minute engineering changes

A modern production plan must be built to absorb these shocks rather than collapse under them.

5.1. Use intelligent buffers

A well-designed plan includes intentional buffers:

- Time buffers between critical operations

- Capacity buffers on key machines

- Material buffers for long-lead items

- Operator buffers for emergency rework

These buffers, when designed strategically, allow your production planning software to adjust without generating chaos each time an event occurs.

5.2. Define contingency scenarios

Your planning tool should support:

- Alternate routes (backup machines)

- Replacement operations when tools are unavailable

- Split lots to maintain flow in case of constraints

Such scenarios turn a rigid production schedule into a more robust dynamic scheduling system.

5.3. Adjust in real time

When the unexpected happens, your production plan should not require hours of manual fixing. A modern production planning software will:

- Recalculate load on each machine

- Reassign jobs where possible

- Estimate new due dates

- Highlight at-risk orders

This enables planners and supervisors to take informed decisions quickly, instead of firefighting blindly.

6. Measure, Analyze, and Continuously Improve Your Planning

Planning is not a one-time project; it’s an ongoing process.

6.1. Track key scheduling KPIs

To improve your production scheduling, monitor:

- Schedule adherence (planned vs actual)

- Machine utilization and OEE

- Overtime vs planned labor

- Real vs planned changeover times

- Queue lengths at bottleneck machines

- On-time delivery performance

These data points help refine both your production plan and your scheduling rules.

6.2. Use shop-floor feedback

Operators and supervisors are invaluable sources of insight. They are often the first to see:

- Unrealistic schedule assumptions

- Repeated bottlenecks in the same area

- Parts systematically underestimated in time

- Operations that constantly get reworked

Integrating their feedback into your manufacturing planning process helps make the production schedule more robust and closer to reality.

6.3. Continuously improve your planning model

High-performing plants regularly revisit:

- Standard times and routing data

- Setup and changeover parameters

- Capacity assumptions

- Skill matrices and staffing models

This continuous improvement loop ensures that your planning software remains aligned with how your factory operates, not how it operated three years ago.

Conclusion: Planning as a Strategic Lever for Your Machine Tools

A high-performance planning function rests on three strong pillars:

- A modern production planning software: Capable of generating automatic, dynamic, and realistic schedules based on your real constraints.

- A clear production scheduling strategy: That prioritizes bottlenecks, manages changeovers, and protects critical orders.

- A culture of continuous improvement: Fueled by real data, operator feedback, and proactive adjustments to the production plan.

Manufacturers that invest in these three pillars see:

- Reduced downtime

- Higher machine utilization

- Better on-time delivery

- Lower operating costs

- A more stable and predictable production schedule

In a world where every minute of spindle time counts, mastering how you plan operations on your machine tools is not just a technical exercise, it’s a strategic advantage.